ePLA-LW

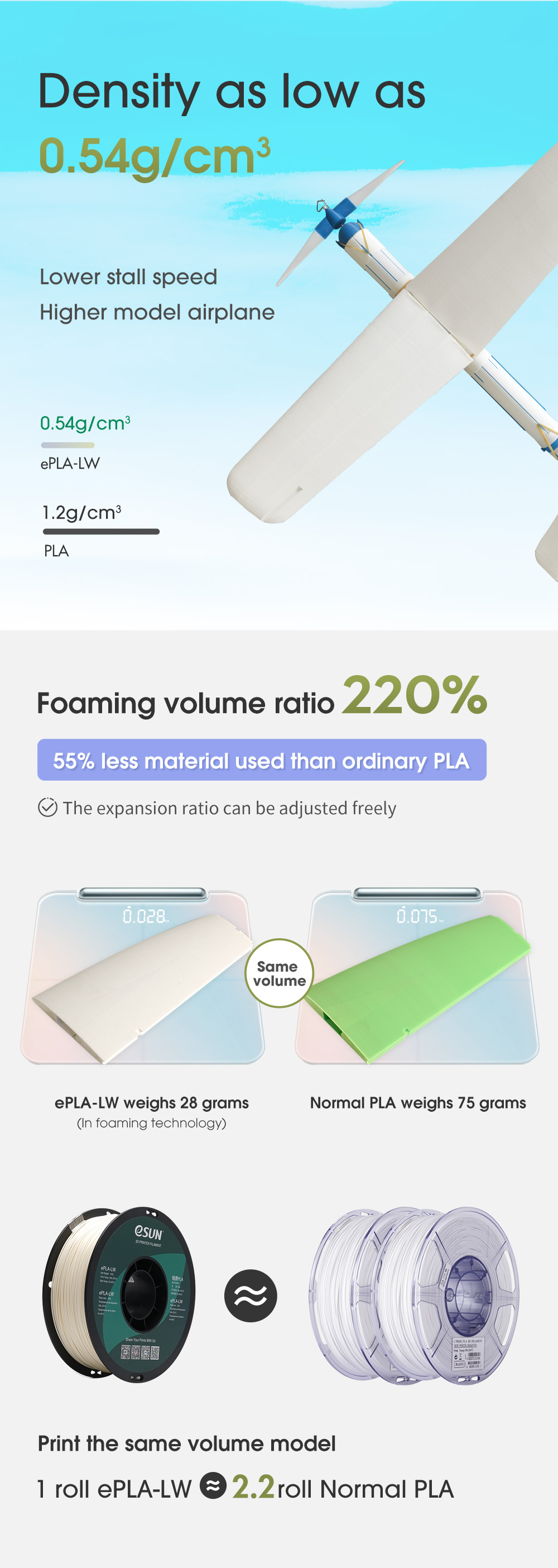

Light weight pla filament is a material specially developed for aeromodelling. The interlayer bonding is stable, and the foaming rate and strength can be controlled by adjusting the printing temperature. ePLA-LW use active foaming technology to achieve lightweight, low-density PLA parts, the foaming volume ratio is 220%, and the density is as low as 0.54g/cm3.

- * Description:

-

Description

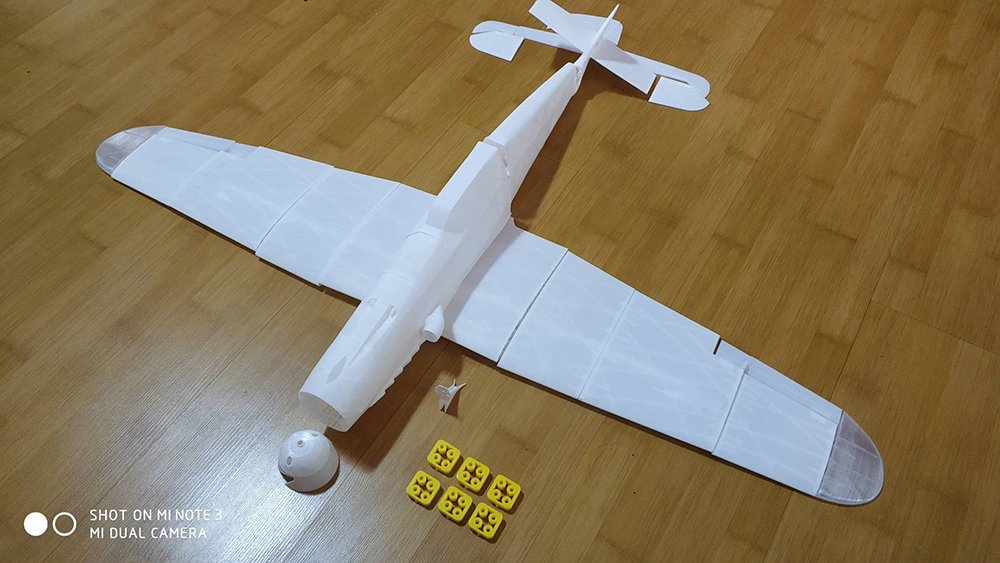

Foaming makes the layered pattern almost invisible, and the surface of the printed item is matte and delicate. Under the same model and at the same speed, the Light weight pla filament enables the model aircraft to have a lighter wing load and a lower stall speed, which can greatly improve the performance of the model aircraft.

Sellingpoint

Density as low as 0.54g/cm3

Foaming volume ratio 220%

Free adjustment of strength and foaming ratio

Excellent matte surface effectGood interlayer adhesion

Easy to paint

Excellent printabilityTips

Notes

1. Note that the first layer speed setting is consistent with the actual printing speed, set to 100% of the actual printing speed, turn off the first layer and small area printing speed reduction function, the first layer extrusion rate is consistent with the actual foaming extrusion rate, such as 270 degrees set to 45% of the first layer extrusion rate; if the bed adhesion is too strong, you can set the bottom valve when printing.

2. Pay attention to the maximum operating temperature of the printer. Most Teflon tube printers cannot be operated for a long time above 250℃. Long-term printing above this temperature may cause blocking. If the temperature exceeds 250℃, high temperature printers such as metal hoses are required for printing.

3. Yellowing of printed parts after high temperature foaming is a normal phenomenon. Lowering the printing temperature can relieve it.

4. Since the ePLA-LW foams continuously in the melting cavity of the high-temperature nozzle, the retraction basically does not work. Stringing is normal during printing. It is recommended to print the rc plane in vase mode to reduce the effect of stringing.

5. Foaming ratio is related to temperature, printing speed, nozzle melting cavity size, pay attention to compare model design wall thickness according to your own printing situation, adjust extrusion rate, temperature, speed and other parameters.

View more about PLA Filament

- * Product introduction video

-

- * Application

- * Print model

-

_191.jpg)

Click to view more detailed printing parameters

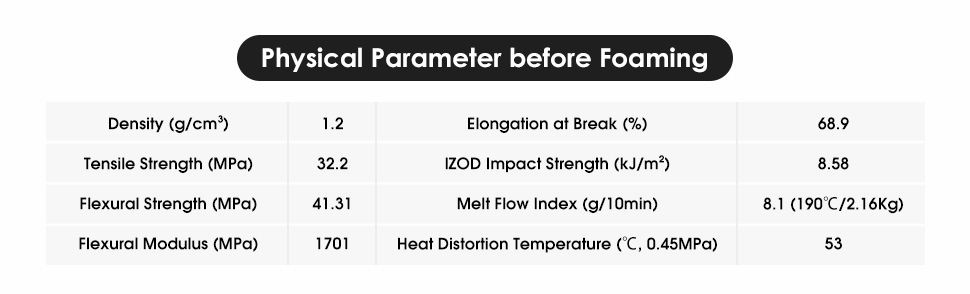

| Filament Properties Table | |

|---|---|

| 3D PRINTING FILAMENT | ePLA-LW |

| Density(g/cm3) | 1.2 |

| Heat Distortion Temp(℃,0.45MPa) | 53 |

| Melt Flow Index(g/10min) | 8.1(190℃/2.16kg) |

| Tensile Strength(MPa) | 32.2 |

| Elongation at Break(%) | 68.9 |

| Flexural Strength(MPa) | 41.31 |

| Flexural Modulus(MPa) | 1701 |

| IZOD Impact Strength(kJ/㎡) | 8.58 |

| Durability | 4/10 |

| Printability | 9/10 |

| Recommended printing parameters | |

| Extruder Temperature(℃) | 190 – 270℃ |

| Bed temperature(℃) | 45 – 60°C |

| Fan Speed | 100% |

| Printing Speed | 40 – 100mm/s |

| Heated Bed | Optional |

| Recommended Build Surfaces | Masking paper, PVP solid glue, PEI |

| Feature | |

| Flexible | —— |

| Elastic | —— |

| Impact Resistant | —— |

| Soft | —— |

| Composite | —— |

| UV Resistant | —— |

| Water Resistant | —— |

| Dissolvable | —— |

| Heat Resistant | —— |

| Chemically Resistant | —— |

| Fatigue Resistant | —— |

| Need drying | —— |

| Heated Bed Required | —— |

| Print recommend | View Notes |

-

ePLA-LW HS Parameters for

ePLA-LW HS Parameters for

Bambu Lab & Creality -

MSDS

MSDS -

TDS

TDS -

ROHS

ROHS -

REACH

REACH