Castable Resin For Jewelry

The resin developed for jewelry casting; very little burning ash and residues, good casting performance, can produce high-quality jewelry pieces; high precision, the details of the fine and complex models in the jewelry industry are clearly visible; used for the loss of gold, silver and copper ornaments Wax casting.

- * Description:

-

Description

The resin developed for jewelry casting; very little burning ash and residues, good casting performance, can produce high-quality jewelry pieces; high precision, the details of the fine and complex models in the jewelry industry are clearly visible; used for the loss of gold, silver and copper ornaments Wax casting.

Sellingpoint

Ash free

High precision

- * Application

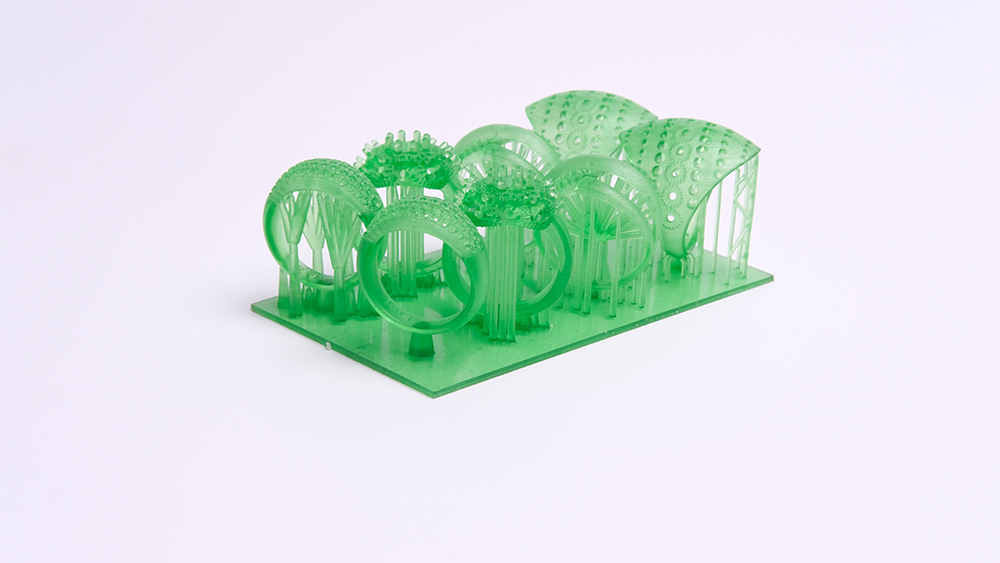

- * Print model

-

| 3D PRINTING PHOTOPOLYMER RESIN Properties Table ( *Recommended Settings For Printer can be viewed by visiting “Download”) | |

|---|---|

| 3D PRINTING PHOTOPOLYMER RESIN | Castable resin For Jewelry |

| Viscosity(mPa·s) | 100-150 |

| Density(g/cm3) | 1.05-1.12 |

| Tensile Strength(MPa) | 42-62 |

| Elongation at Break(%) | 11-20 |

| Flexural Strength(MPa) | 49-58 |

| Impact Strength(J/m) | 44-49 |

| Tearing Strength(GPa) | / |

| Heat Distortion Temp(℃) | / |

| Hardness(Shore D) | 60 |

| Grades (out of 10) | |

| Strength(S) | 8 |

| Toughness(F) | 7 |

| Forming(P) | 9 |

| Accuracy(S) | 8 |

| Speed (A) | 4 |

1. Shake well before printing

2. Jewelry casting resin needs to be fully cured to achieve the best mechanical strength. It is recommended that the surface is cured until it is not sticky.

-

REACH

REACH -

ROHS

ROHS -

TDS

TDS -

Castable resin for Jewelry Recommended Settings For Printer

Castable resin for Jewelry Recommended Settings For Printer