High Temperature Resin

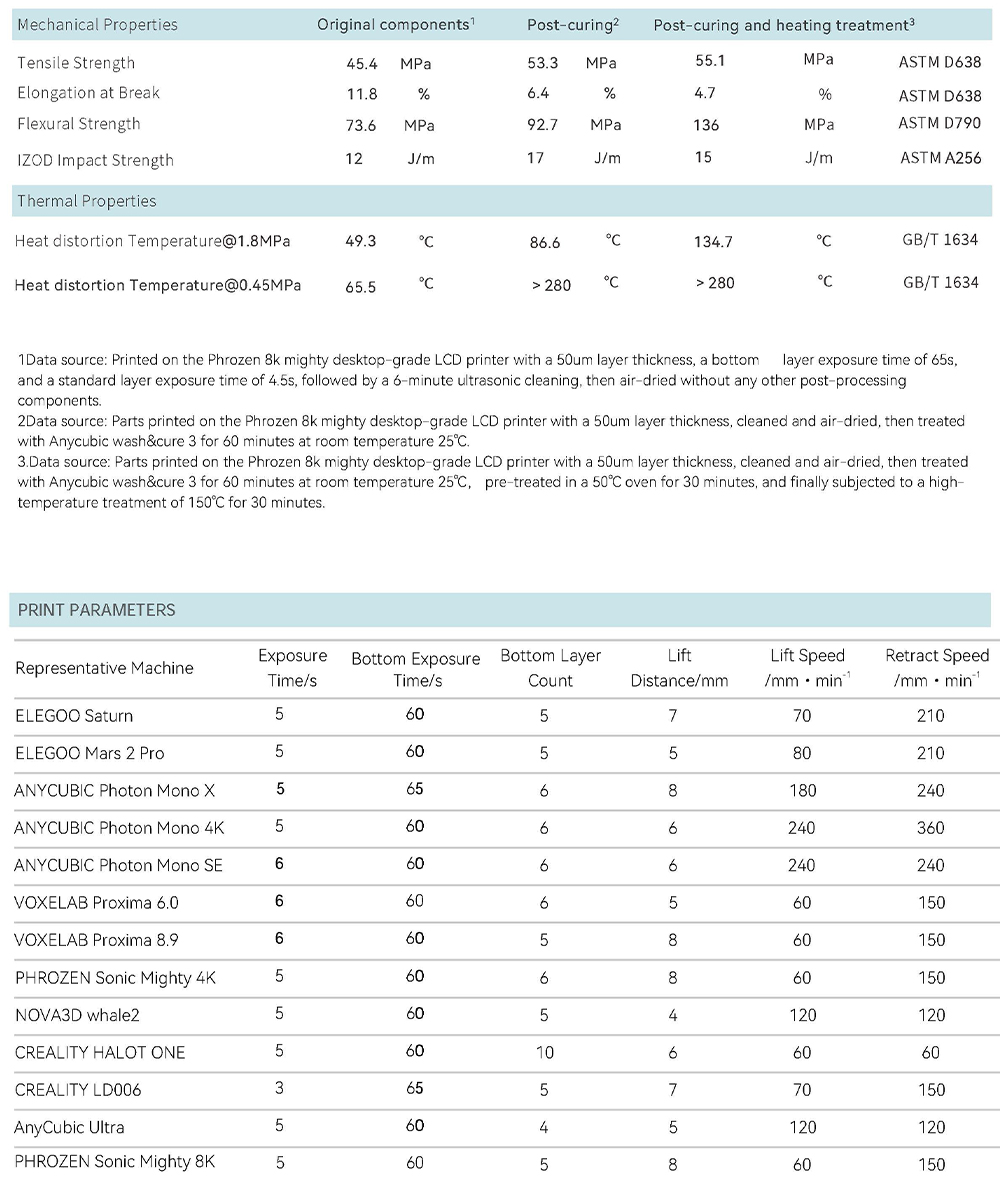

High Temp Resin thermal deformation temperature can reach over 280 ° C, maintaining good dimensional stability and shape integrity in high-temperature environments.

Color:

Net Weight:

- * Description:

-

Description

High Temp Resin thermal deformation temperature can reach over 280 ° C, maintaining good dimensional stability and shape integrity in high-temperature environments.

Sellingpoint

Heat Resistance Over 280°CHigh HardnessHigh StrengthHigh Precision

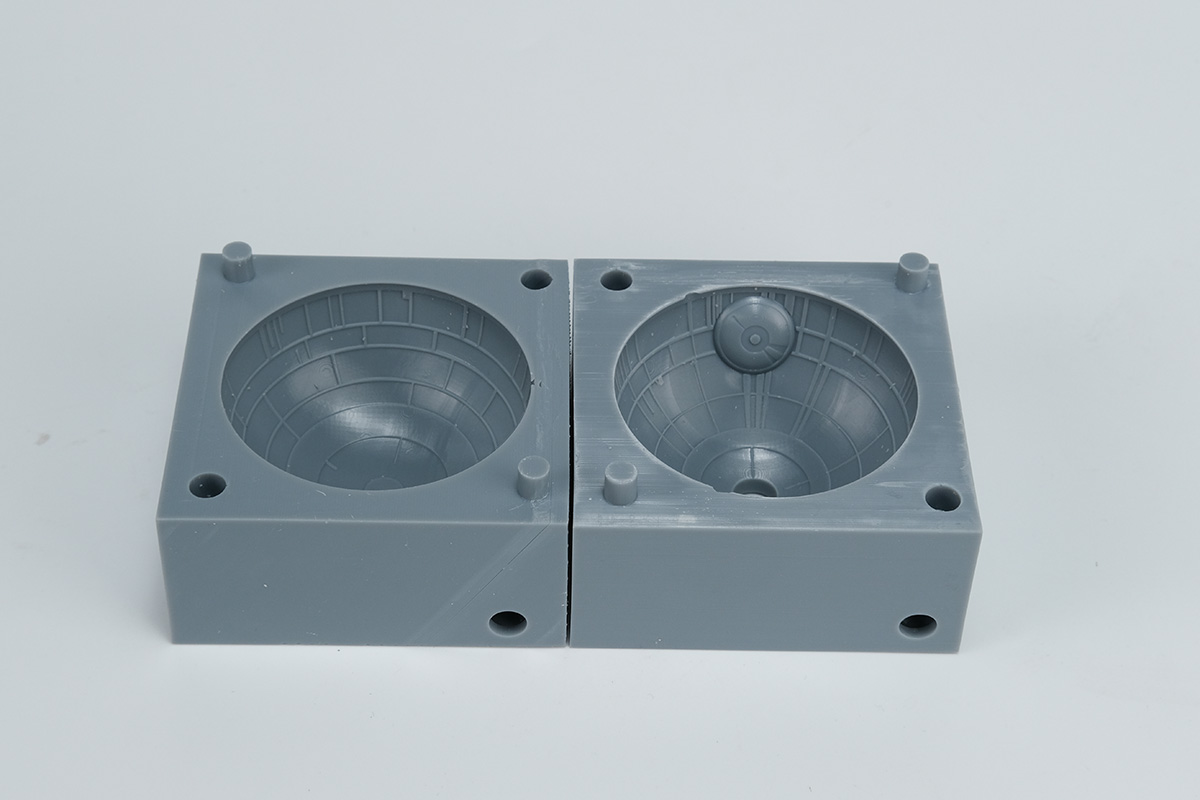

- * Application

- * Print model

-

1.Shake well before printing

2.After printing, it should be fully cured (more than 10min), and then put in the oven at 150℃ for 30min. The support can be removed after the post-processing

3. The wall thickness of the heat-resistant parts can be as thick as possible to achieve the heat-resistant performance, and the heat treatment time in the oven should not be too long

-

HT100-High-Temp-Resin_MSDS

HT100-High-Temp-Resin_MSDS -

H100 High Temp Resin_TDS_V5.0

H100 High Temp Resin_TDS_V5.0