3D Printed Custom Insole System

The medical insole market is developing rapidly with the increasing health awareness of consumers and the increase in diabetic patients. The global foot insole market is growing at a compound annual growth rate (CAGR) of 7.50% and is expected to grow to USD 1.41 billion between 2021 and 2025. However, compared with mature markets such as Europe and the United States, the penetration rate of orthopedic insoles in China is relatively low, and there is still a large room for development in the market. On the one hand, as China’s economic development level continues to improve, and in the context of consumption upgrades, patients’ attention and investment in foot health will increase accordingly. On the other hand, the increase in obesity, abnormal foot development in children, and the intensified aging trend have all put forward higher requirements for the applicability and universality of medical insole products.

At present, in the field of rehabilitation medicine, traditional production technology can no longer fully meet the needs of patients. 3D printing technology has its advantages of individualization, which is small batches and high precision. It can easily solve the problems of individual differences among patients and build a personalized health industry. The gap between demand and production scale helps medical device manufacturers improve their production flexibility, also assisting doctors or researchers to bring better precision medicine solutions to patients.

.jpg)

The iSUN3D 3D digital custom orthopedic insole system integrates the “Scanning-Diagnostic design-3D printing-Post processing” technology to provide each customer with a unique customized insole. Using a new scanning technology to obtain the 3D data of the sole, through the professional knowledge of the orthopedist, use the special design software for the insole to design the insole that is most suitable for the customer’s foot shape, and then use the special 3D printer for the insole and the material to print it in one piece. Enable users to obtain orthopedic insoles that are more suitable, more efficient, environmentally friendly, and more comfortable.

3D printed custom insole system module

Scanning Module: single/bipedal scanner to meet the needs of a variety of scenarios, easy operation, high-speed scanning, accurate modeling, cloud computing function, automatic generation of professional reports, convenient transportation

Evaluation module: dynamic/static measurement; Support medical, motion analysis algorithms; Simple to use; Easy to read; Has an intelligent cloud data management system; Various products meet the needs of various scenarios

Design module: Easy to use without design experience; Supports input and output of files in various formats; Powerful functions; Various types, modes and accessories are free to choose for users to design freely

Production module: double-station high-speed printing; supporting material break detection; adapting to a variety of flexible materials; printing a pair of orthopedic insoles in 30-50 minutes

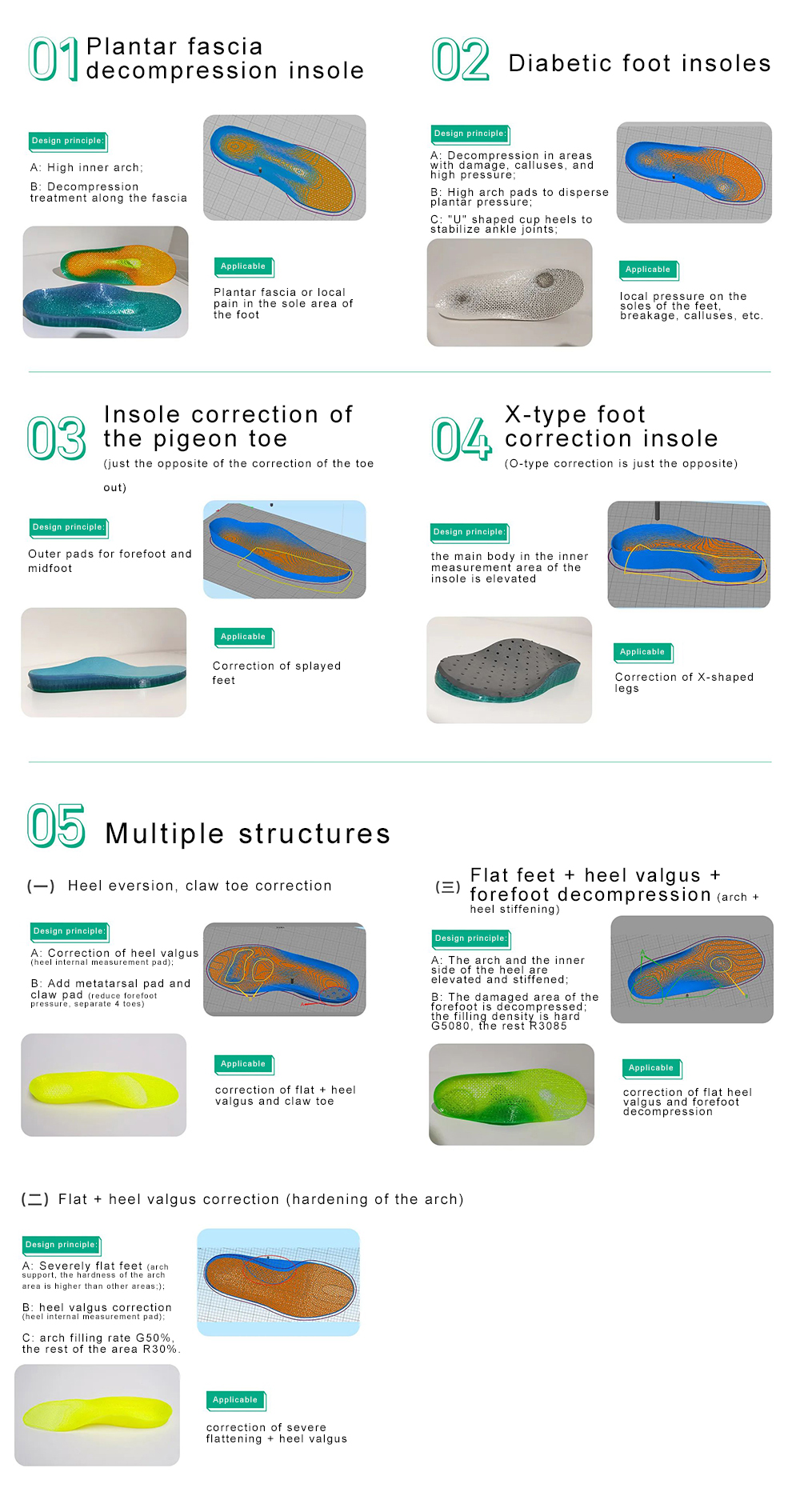

3D printing custom insole applications

The iSUN3D customized insole system has been successfully applied in the foot, spine clinics and rehabilitation institutions of many hospitals, and is playing an increasingly important role in foot orthopedics.

The following are some application scenarios of 3D printing custom orthopedic insoles. 3D printed orthopedic insoles can use different wiring arrangements and printing densities according to the user’s actual situation to achieve the different hardness and functions in each area. Provide foot cushioning and stable support while ensuring the arch structure, meet the needs of different types of customers, and achieve highly convenient personalized customization.

Join us

Training support: Provide professional knowledge training, equipment operation training, sales training, marketing training, etc.

Material support: Provide samples, promotional copy, PPT, promotional video, etc.

Technical support: The design center provides full assistance and endorses various professional qualifications.

After-sales support: Perfect after-sales mechanism, response 24/7.

Hotline: 0755-86581960

Visit the website to learn more: https://www.isun3d.net/ to learn more!

Post time: May-28-2023