eSUN new lightweight PLA launched for RC Planes and COSPLAY!

2021/04/12

eSUN new lightweight PLA launched for RC Planes and COSPLAY!

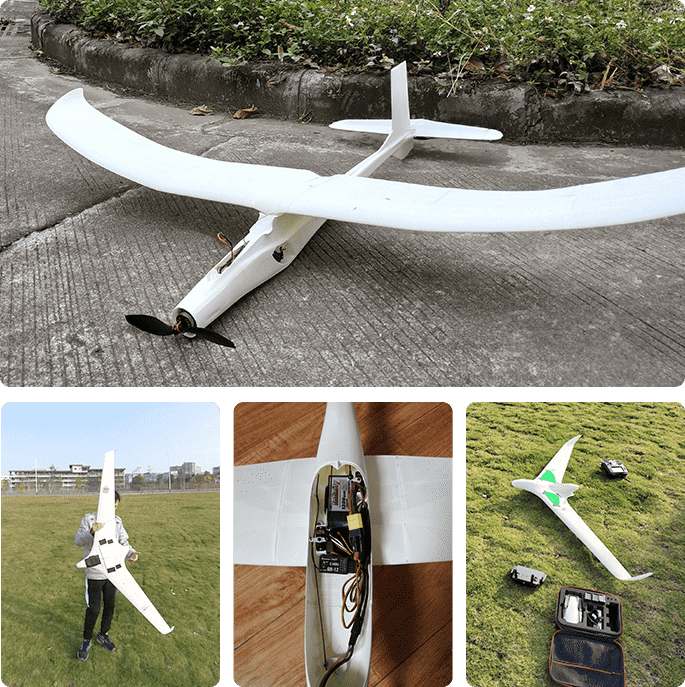

In recent years, 3D printing RC Planes and 3D printing COSPLAY props have rapidly emerged with the rapid popularization of 3D printing technology. Compared with traditional production methods, the flexibility and diversity of 3D printing gives users more choices and greater freedom of creation.

Video display of 3D printed RC Plane flight test:

1.1.4m glider test flight video

2.1.8m fpv flying wing test flight video

3. Water machine flight test video

The above 3D printed airplanes are all made with eSUN ePLA-LW lightweight PLA. According to feedback from RC Planes enthusiasts, eSUN ePLA-LW has more prominent advantages than PLA and other materials that have been used more before.

So, what are the key point regarding to choosing the filaments for 3D printing RC Planes? What are the advantages of ePLA-LW? Let’s find out now!

About 3D printing RC Plane

3D RC Planes can be divided into 3D printed airplanes and 3D printed parts. From traversing aircraft to fixed-wing personalization, from functional parts to fixed-wing complete aircraft, and helicopter parts, 3D printing are all involved.

As a kind of self-made machine, 3D RC Planes has the advantages of simple production, short manual labor hours, high image fidelity, much lower production cost than that of commercial machines, and the body curve is smooth and natural. It has a more real appearance than the kt board and pp board self-made machines, which is close to or even surpasses the commercial products. The wing load can also approach or surpass the kt plate, which is lighter than the self-made aircraft such as epp. The difficulty in the production process is relatively low. Compared with self-made machines such as hot-cut foam, glass fiber reinforced plastic, and balsa wood, it does not require a larger production space, more tools or complicated skills.

The construction of the fuselage is completed by a 3D printer, which has a high degree of freedom. In the process of constructing a 3D RC Plane, the producer can easily change the size of the model, select printing materials with different properties, and control the density of the materials. Finally, compared to commercial airplane models, 3D RC Planes are generally cheaper and have more creative possibilities.

At present, there are many common materials for 3D RC Planes. From the relatively widely used PLA, ABS, TPU, PETG, etc., to the foamed PLA which has replaced the traditional PLA in recent years, it is used according to the different needs of users and different use occasions. The materials are also different.

|

Types of airplanes |

commodity airplanes |

Self-made airplanes |

|||

| Commonly used materials | EPO foam, balsa wood, FRP | KT board, PP board, EPP, balsa wood, FRP, carbon brazing | PLA+、ABS、TPU、PETG | Wood | ePLA-LW |

| Advantage | Hand fly, tear resistance, scratch resistance and chip resistance, easy to repair, moderate weight | Control wing load, model, size, price, configuration, performance, low price, simple production | Inexpensive and easy to print | Easy to print, low density, light wing load | Easy to print, low density, light wing load, free adjustment of strength-foaming ratio, good finish surface, easy coating, drop resistance, easy repair |

| Disadvantages | High performance limitations, no price advantage, high production difficulty, and no modification | Long labor time and poor surface transition | General temperature resistance, high density, heavy load like real wing, general adhesion between layers, not falling | General temperature resistance, general adhesion between layers, not resistant to falling, not easy to repair | General temperature resistance |

The appearance of foamed PLA is not long, but it has obvious advantages as a RC Plane material. The most important point is lightness. The RC Plane printed with foamed PLA has a lighter weight than the KT board, epp, PP board and other RC Planes pursuing light-wing load. At the same time, foamed PLA can also adjust the temperature of the print nozzle to change the density of the material, from the high-strength and heavy-weight plastic form to the density of balsa wood and the density of foam, thereby realizing more creative possibilities.

About ePLA-LW (Lightweight PLA)

eSUN ePLA-LW (also known as foamed PLA) is specially developed for RC Plane, drones, and COSPLAY. Compared with WOOD, ePLA-LW has more stable interlayer bonding, and the foaming rate and strength can be controlled by adjusting the printing temperature. Use active foaming technology to achieve lightweight, low-density PLA parts.

ePLA-LW features:

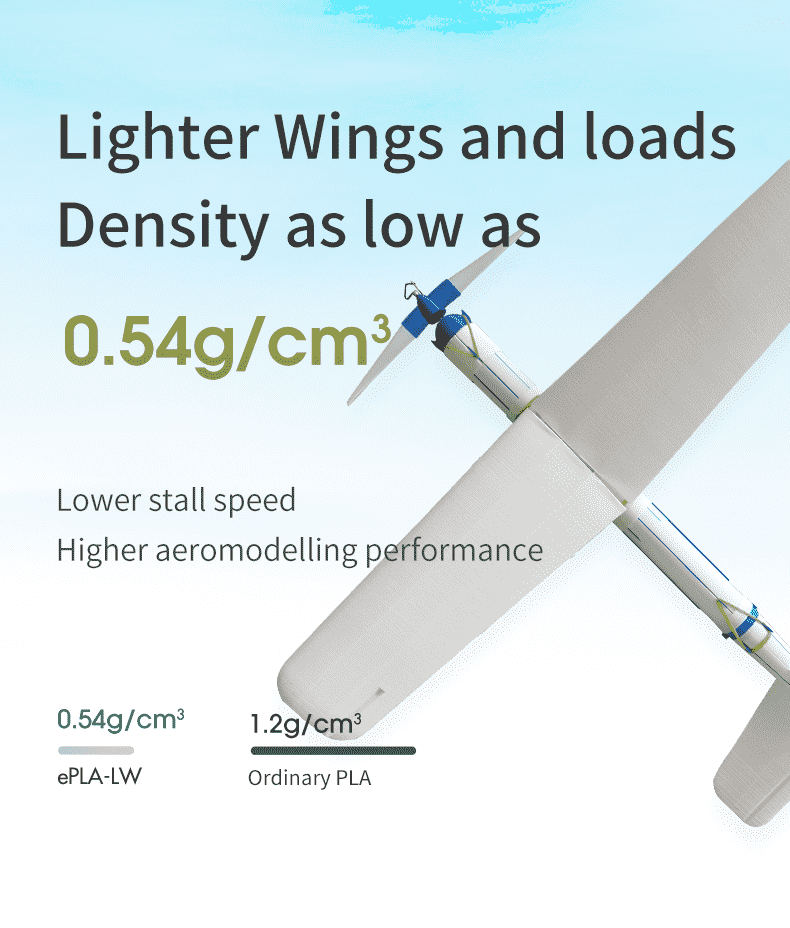

1. Low density, up to 0.54g/cm³;

2. Foaming volume ratio 220%, for printing the same volume model, 1 roll of ePLA-LW can be used as 2.2 rolls of ordinary PLA;

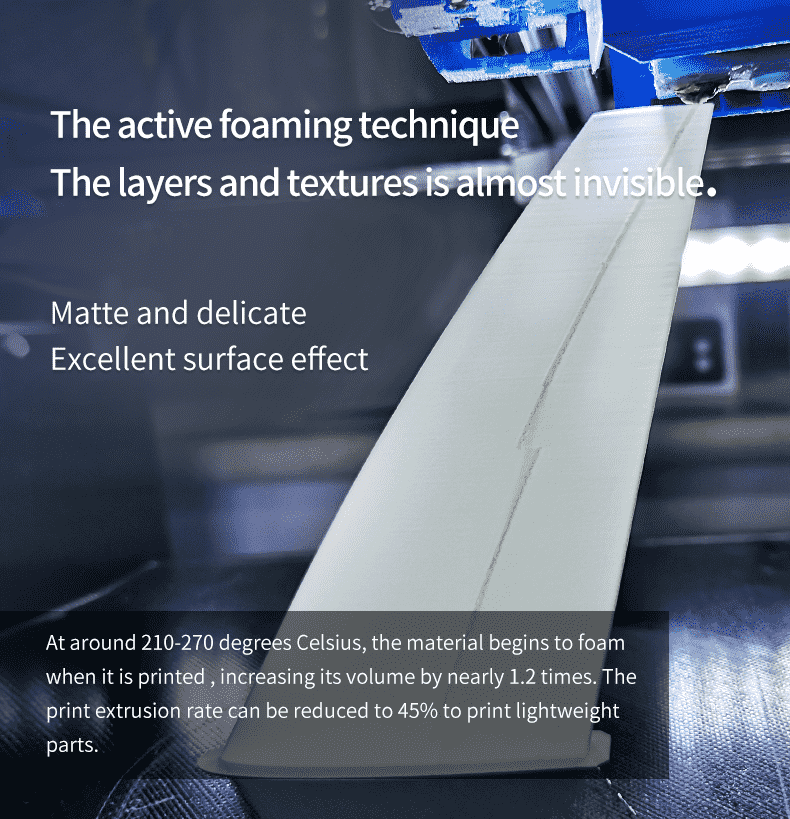

3. Foaming makes layer lines basically invisible, and the surface of the printed item is matte and delicate; at about 210-270℃, this material starts to foam during printing, increasing the volume by nearly 1.2 times, and the printing extrusion rate can be reduced to 45% to print lightweight parts.

4. The strength and foaming ratio can be adjusted freely;

5. Possess excellent interlayer strength, explosion resistance and easy repair;

6. The printed model is easy to paint and has strong surface adhesion.

With the same model situation and same speed, the use of lightweight PLA can make RC Plane a lighter wing load and a lower stall speed. For RC Planes, in the case of balanced strength, reducing the weight as much as possible can greatly improve its performance.

ePLA-LW application areas:

ePLA-LW is mainly used for lightweight parts, and is widely used in DIY RC Planes, drones, and COSPLAY props.

3D printed RC Plane display:

ePLA-LW parameters:

1. Physical performance indicators of unfoamed filaments:

|

3D打印材料 |

测试方法/标准 |

ePLA-LW |

|

熔融指数 |

GB/T 3682-2000 |

8.1(190℃/2.16kg) |

|

密度 |

GB/T 1033-86 |

1.2g/cm³ |

|

悬臂梁缺口冲击强度 |

GB/T 1843-96 |

8.58kJ/㎡ |

|

拉伸强度 |

GB/T 1040-92 |

32.2MPa |

|

断裂伸长率 |

GB/T 1040-92 |

68.90% |

|

弯曲强度 |

GB/T 9341-2000 |

41.31MPa |

|

弯曲模量 |

GB/T 9341-2000 |

1701MPa |

2. ePLA-LW printing parameters:

|

Material name |

ePLA-LW |

|

Recommended printing temperature |

190-270℃ |

|

Unfoamed printing temperature |

190-210℃ |

|

Foam printing temperature |

210-270℃ |

|

Maximum foaming temperature |

270℃ |

|

Maximum foaming rate (270℃) |

122% |

|

The lowest extrusion rate (270℃) |

45% |

|

Base plate temperature |

45-60°C/no heating (Masking paper, PVP solid glue, glass board, carbon fiber board, PEI) |

|

printing speed |

40-80mm/s |

3.Comparison of printing performance index of ePLA-LW and Wood filament:

|

Filament |

Wood |

ePLA-LW |

|

Foaming process |

Foaming duringproduction Nofoamingwhen printing |

No foaming during production Foaming when printing |

|

Interlayer bonding |

General |

Strong |

|

Density |

0.7 |

Up to 0.54 |

|

Foaming ratio |

No |

210-270℃ |

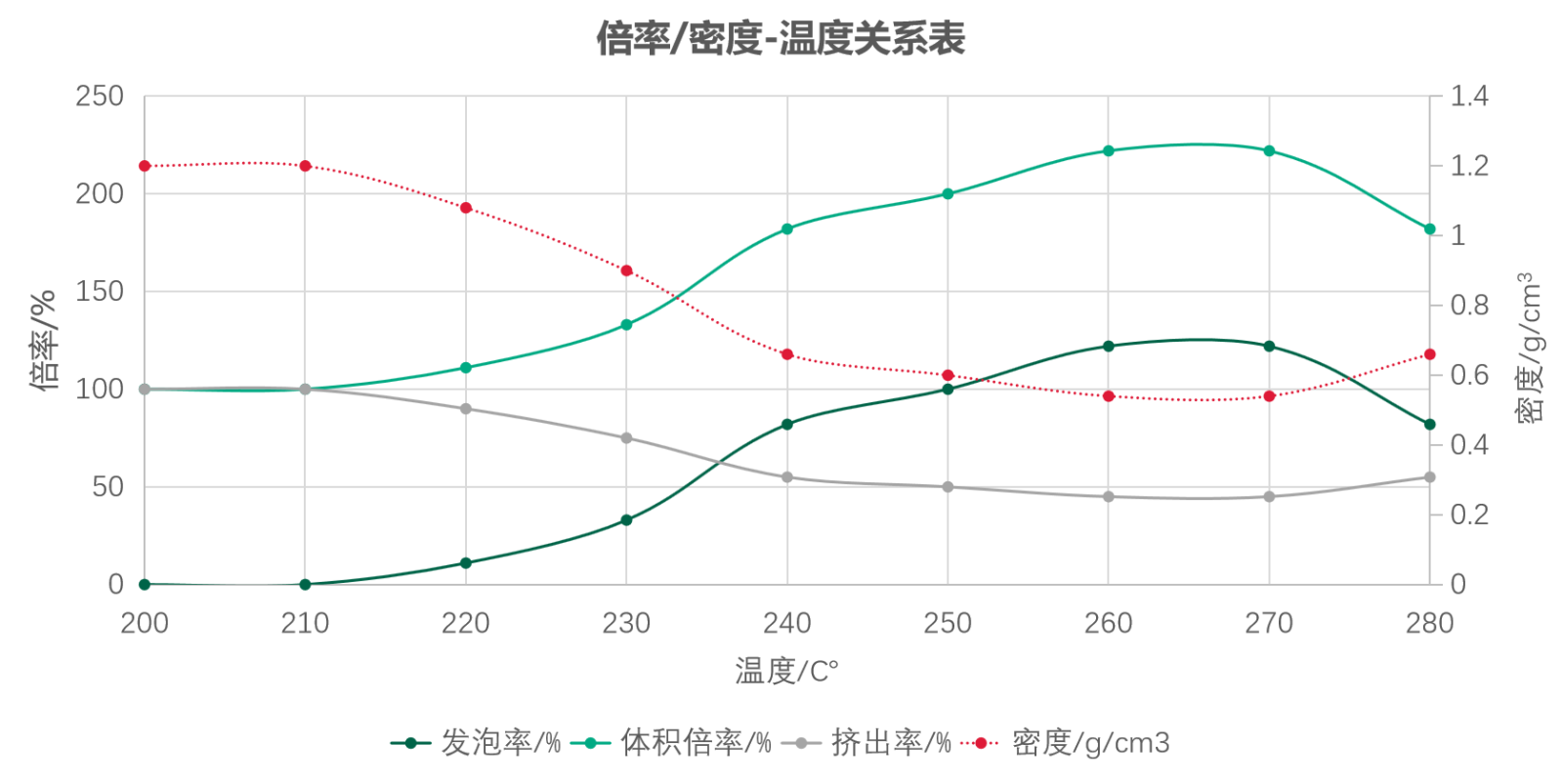

4. Different temperature foaming ratio

|

Temperature/℃ |

200 |

210 |

220 |

230 |

240 |

250 |

260 |

270 |

280 |

|

Foaming rate/% |

0 |

0 |

11 |

33 |

82 |

100 |

122 |

122 |

82 |

|

Volume ratio/% |

100 |

100 |

111 |

133 |

182 |

200 |

222 |

222 |

182 |

|

Extrusion rate/% |

100 |

100 |

90 |

75 |

55 |

50 |

45 |

45 |

55 |

|

Density/g/cm³ |

1.2 |

1.2 |

1.08 |

0.9 |

0.66 |

0.6 |

0.54 |

0.54 |

0.66 |

|

speed |

40mm/s |

||||||||

5. Temperature-rate relationship table

eSUN ePLA-LW has been deeply recognized by DIY enthusiasts since the testing stage. Please feel free to contact us if you have any questions!

Recommended reading:

1. New ePLA-LW performance and industry application introduction

2. Application of 3D printing in RC planes

3. 3D printing RC planes, what are the characteristics and advantages of different materials?

Contact details:

Phone number: 0755 26031978

Email: bright@brightcn.net

QQ: 2304729480

WeChat: GWWYeSUN

Or leave a message at the end, we will get in touch with you as soon as possible!