3D Printing Repair Tool, ePA12-CF Reliable!

With the development and progress of the industry, 3D printing is widely used in the prototype development or mass production of automotive components. As an emerging force, the advantages of 3D printing technology in the automotive industry include higher efficiency and design flexibility, while also helping to reduce material waste and improve accuracy and precision.

It is not uncommon for “big factories” to directly customize the production of cars and related components through 3D printing. So, what convenience can 3D printing technology bring to individual players?

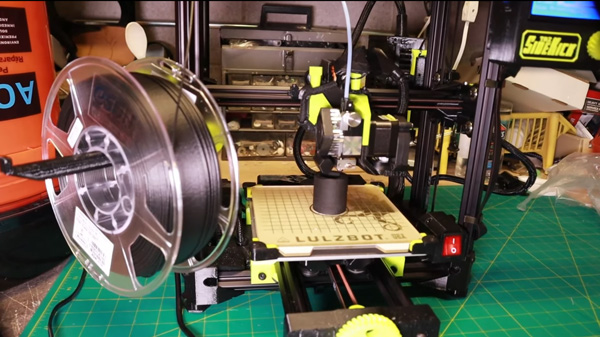

The case we are going to introduce today is from a Canadian blogger named Maddy_ Deee (Tiktok). The blogger excels in 3D modeling and 3D printing creation, and tests the performance limits of 3D printing materials in some fresh and interesting ways to expand the application scenarios of 3D printing technology in daily life.

The protagonist of this issue’s material is eSUN’s ePA12-CF carbon fiber reinforced nylon 12. The author selected PLA and ePA12-CF to print and produce L-shaped wrench sleeves, and successfully verified the feasibility of ePA12-CF in the direction of printing and producing wrench sleeve tools through practical scenario applications – dismantling car tires!

Kind reminder, the recommended printing temperature for nylon carbon fiber materials is 280 ℃ -300 ℃, and non enclosed printing equipment is recommended to be used with a constant temperature box. Due to the easy wear of nylon carbon fiber materials on nozzles and extruder gears, hardened steel nozzles and hardened rigid extruder gears can be used if conditions permit. In addition, moderate drying before printing can improve the printing effect.

Socket is the abbreviation for socket wrench head. The sleeve is divided into two sections. The driving end is sleeved on the driving head of various wrenches, and the acting end is connected to the nut and other workpieces that need to be rotated. Due to its cylindrical shape, it is called a sleeve and is a commonly used tool for automotive repair, assembly, production, and industrial maintenance. A socket wrench is the most convenient, flexible, and safe maintenance tool for disassembling bolts, and using a socket wrench is not easy to damage the edges and corners of the nut.

In order to gain a clearer understanding of the material’s performance, the author used a torque wrench for this test, starting from low torque and gradually increasing by 20 pounds until reaching 100 pounds.

The usually calibrated torque is between 80 and 100 lbs-ft, and 100 pounds is also the recommended number of pounds for the vehicle being tested. According to actual testing, when the torque is 20-60lbs-ft, both PLA and ePA12-CF printed socket wrenches can smoothly rotate the car nut. When the torque increased to 80 lbs-ft, there was wear inside the sleeve printed with PLA material and the nut did not rotate. (However, according to the author’s statement, such performance is still surprising for PLA materials.)

The performance of the sleeve printed with ePA12-CF can meet the requirements of application scenarios very well, and even at a torque of 100lbs-ft, the “task” is successfully completed without any wear on the sleeve.

For more detailed testing details, please refer to the video content below. Thank you also to the original author for providing us with material support.

In fact, nylon material itself is an excellent engineering plastic. After adding 15% carbon fiber, it greatly enhances the strength, rigidity, toughness, and wear resistance of nylon, and can be used as a substitute for metal in multiple occasions. This product is the material with the lowest water absorption in the eSUN nylon series, and its size and electrical properties are less affected by humidity and temperature. The printed model has high dimensional stability and good mechanical performance. At the same time, ePA12-CF has excellent chemical resistance. As a star product jointly developed by eSUN and LUVOCOM, it has guaranteed quality and can be widely used in various occasions and fields!

In the automotive industry, due to the excellent oil resistance, wear resistance, and creep resistance of materials, as well as their lightweight advantages, they can be used to manufacture engine components, electrical components, and vehicle body components. At the same time, its excellent fatigue resistance can also be applied to the manufacturing of synchronous drive gears for automotive internal combustion engines.

In addition, ePA12-CF can also be applied in various fields such as industrial manufacturing and sports, including helmets, car crash barriers, robotic arms, drones, etc. Welcome everyone to continue exploring!

The development of materials helps to expand the application scenarios of 3D printing technology. In the future, eSUN will continue to optimize product performance and keep up with industry development trends, providing stable support and guarantee for creation and professional applications with diverse 3D printing materials!

Printed by Maddy Deee Media

Click to view the original