eSUN Engineering 3D Printing Filament

3D printing technology has injected new impetus into industrial development. 3D printing materials are crucial to the development of equipment and related software, the development of the 3D printing industry as well as the popularization of related technologies. Among them, engineering-grade 3D printing materials are currently the most widely used. Common engineering 3D printing materials include ABS, PA, PC, TPU, TPE, etc.

In eSUN’s existing engineering 3D printing material, PLA series products are also included. As we all know, among the currently used 3D printing plastic substrates, although polylactic acid (PLA) is widely used, it also has obvious performance defects. The material itself is brittle, and it is easy to have nicks and breakage when it is dropped or hit. Thin parts are also easy to break when bent. The poor heat resistance limits the further promotion and development of PLA materials in the field of 3D printing to a certain extent. application.

Based on the above problems, eSUN has developed a variety of PLA modification technologies and successfully applied them in the production process of materials. Among them, two representative PLA series engineering materials are ePLA-ST and ePLA-GF.

I. ePLA-ST and ePLA-GF

1. ePLA-ST

ePLA-ST is an engineering-grade 3D printing filament developed by eSUN based on PLA toughening modification technology. It has the advantages of high bonding strength, high printing accuracy, high precision, smooth printing, resistance to light aging, air oxidation resistance, etc., which is suitable for long-term continuous printing and can be applied to printing guard plates and structural parts, etc.

2. ePLA-GF

ePLA-GF is a printing consumable based on PLA, with 16% glass fiber added, which greatly enhances the rigidity, impact resistance and wear resistance. The flexural modulus is as high as 4400MPa, and not easy to distort and deform; it also has high impact resistance, and good printability of PLA; suitable for prototypes of mechanical parts that require rigidity and impact resistance; wear resistance. It can be used as a temporary functional part.

Ⅱ.ABS and ASA

1. ABS Max

eABS Max is based on ABS modification, has higher mechanical properties, has UL94V-0 level flame retardant performance, which is safer; has higher toughness and impact resistance. It can print durable parts for some outdoor and high-temperature applications.

2.eASA

The characteristics of eASA are similar to ABS, but it is more resistant to ultraviolet light and harsh weather conditions, strong toughness, strong rigidity, and high impact resistance; it has excellent weather resistance and mechanical properties, making it more resistant to environmental aging. It is usually used in outdoor applications.

Ⅲ.TPU and TPE

1. eFlex (TPU-87A)

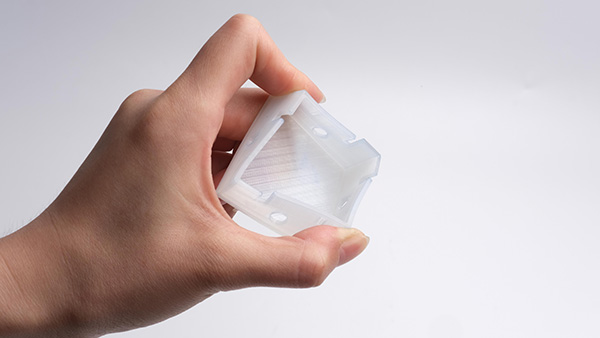

This material is a transparent flexible TPU consumable with a hardness of 87A, which is strong and durable, and the printed product is softer than TPU-95A and has a certain degree of transparency.

2. eLastic(TPE-83A)

The hardness of this material is 83A, and its characteristics are basically similar to eFlex. It is strong and durable, and it is also a flexible material with high elastic mechanical strength, good wear resistance and aging resistance. The printed model feels m softer than TPU-95A, and has low surface friction.

Ⅳ.PA Nylon material

1. ePA

ePA is a printing consumable based on nylon 6/66 copolymer; its self-lubricating and wear-resistant properties make it suitable for printing gears; it has high toughness and impact resistance, and its elongation at break is as high as 175%, which can be used for printing with high resistance Fragmentable strong and durable parts; It has low shrinkage quality and less prone to warping and cracking when printing.

2. ePA-CF

ePA-CF adds 20% carbon fiber on the basis of nylon, which greatly increases the rigidity and strength of the material, and has good wear resistance, impact resistance and temperature resistance. This material can be used instead of metal on many occasions, suitable for printing gears and durable parts.

3. ePA12

ePA12 is a product developed based on nylon 12, which reduces water absorption on the basis of ePA. With low water absorption, the printed part size is less affected by humidity and temperature. ePA12 has high toughness, high impact resistance, and can be used to print durable parts; it has up to 165% elongation at break and excellent fatigue resistance; It has great self-lubricating wear resistance, and can print mechanical gears; It has high-temperature resistance, with a heat distortion temperature of 100°C, and can be used for heat-resistant parts.

4. ePA12-CF

ePA12-CF is a material developed based on PA12 in cooperation between eSUN and LUVOCOM. On the basis of nylon 12, 15% carbon fiber is added, which greatly enhances the strength and rigidity of nylon, and its water absorption is lower than that of PA-CF. At the same time, it also has self-lubricating wear resistance and high-temperature resistance. The continuous use temperature of the parts can reach 120°C, and the short-term use temperature can reach 160°C.

5. ePAHT-CF

ePAHT-CF is a PA6-based material developed in cooperation between eSUN and LUVOCOM, adding 15% high-rigidity carbon fiber, which has high strength, high rigidity, and higher mechanical and thermal properties than other eSUN nylon series products; It can be used instead of metal in many occasions; the continuous use temperature of the parts can reach 150 ℃, and the short-term use temperature can reach 180 ℃; Due to its low shrinkage rate, it is not easy to warp and crack during printing, and the surface of printed items is matte and delicate.

Ⅴ.PC material

Features: 3D printing materials with excellent mechanical properties, high toughness and impact resistance, stable and durable properties; temperature resistance, heat distortion temperature up to 80 °C.

The above is a brief inventory of eSUN’s engineering 3D printing filaments. It should be noted that there are more precautions for printing engineering-grade materials. Taking nylon materials as an example, the materials are prone to moisture. It is recommended to dry them before printing. If conditions permit, they can be used with moisture-proof material boxes; in addition, nylon materials have high shrinkage performance, so it needs to be printed under a constant temperature sealed box, and the model cooling fan needs to be turned off when printing; finally.

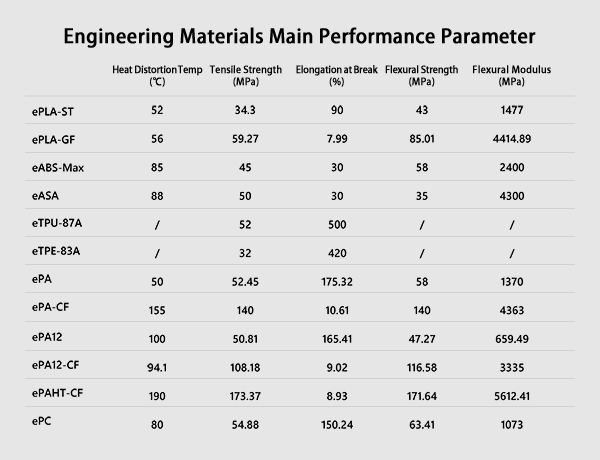

The following are some performance parameters of eSUN engineering 3D printing materials for your reference.