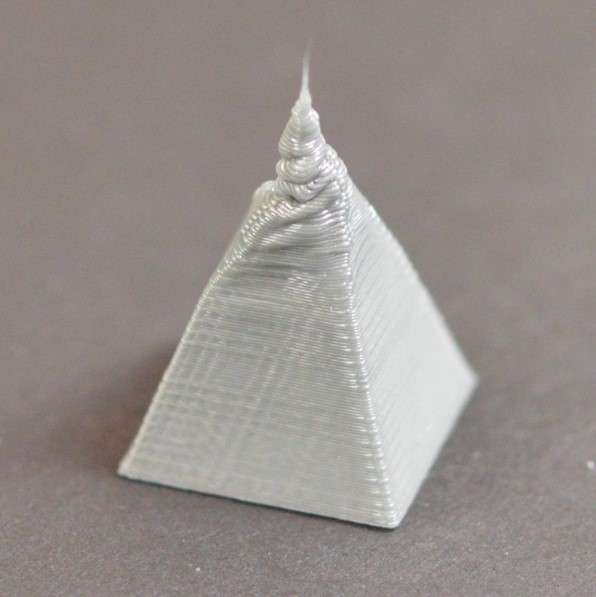

Print distortion

The material temperature is too high, the model can not be quickly cooled and shaped and melted, the printing deformation is mainly related to the material cooling and blowing fan.

Material: Different materials have different degrees of cooling, and the maximum tilt angle and minimum cooling time that can be printed are different.

Heat dissipation: for PLA, PETG and other materials with low shrinkage but less easy to cool, the higher the speed of the blowing fan the better, but be careful not to blow to the nozzle, or it will lead to nozzle temperature is not enough to plug the head

Slicing: slicing can open a small area to reduce the speed (single-layer printing time below how many seconds to reduce the speed to how much) and a small area to increase cooling (single-layer printing time below how many seconds to increase the ratio of the blowing fan to how much), reduce the thickness of the printed layer, or a single print multiple models to optimize material cooling for better molding

Temperature: the higher the temperature, the more difficult to cool the material, which can reduce the printing temperature to ease

Post time: Sep-05-2021