Surface roughness

Surface roughness is usually related to material, slicing, and temperature.

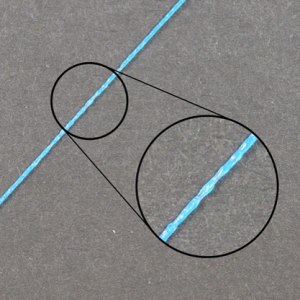

Extruded material expansion explosion

•Material:Material absorbs water, and the water vaporizes and expands at 200 degrees with explosive sound, so it should be dried before printing according to the requirements of different materials (PVA, PA, TPU, PC, PEEK).

•Printing: Easy-absorbent consumables are printed directly in the air and absorb water during the printing process), it should be equipped with sealed material box, such as eBOX.

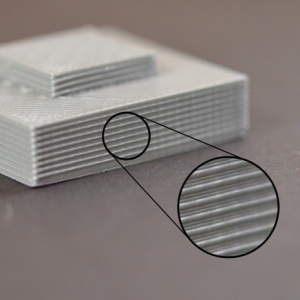

Z-axis horizontal stripes

•Temperature: When the printing temperature fluctuates, the print head PID should be tuned to make the print temperature stable; The hot bed temperature fluctuations, heat transfer hysteresis is obvious, resulting in changes in the temperature cavity, the material produces different degrees of shrinkage, close the hot bed to try or tune PID of hot bed

•Pipe: The pipe has insufficient heat dissipation and the material flow is unstable.)it is recommended to replace the higher speed Pipe fan to accelerate cooling

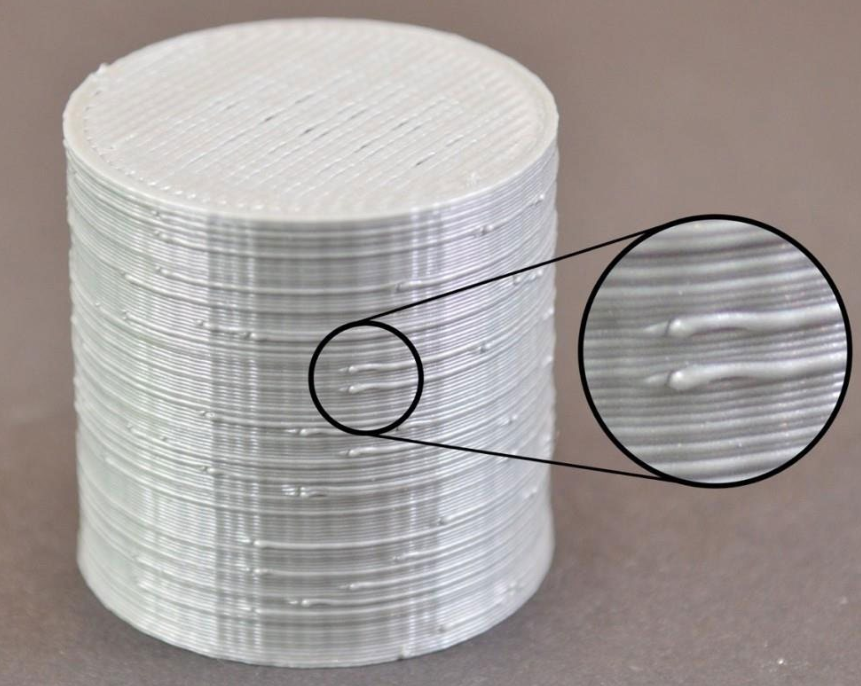

Material shortage or overflow at the starting point

•Drawback: too much drawback or too little drawback compensation will lead to lack of material at the starting point; too little drawback or too much drawback compensation will lead to overflow of material at the starting point; correct adjustment of drawback can make the surface smooth and reduce wire drawing.

Post time: Sep-05-2021