eABS-GF

Adding glass fiber reinforced material and modification in ABS strengthens the rigidity and toughness of ABS, which has excellent impact resistance and chemical corrosion resistance, and has a good performance in some scenes with high strength requirements such as work jigs and fixtures;

- * Description:

-

Description

Adding glass fiber reinforced material and modification in ABS strengthens the rigidity and toughness of ABS, which has excellent impact resistance and chemical corrosion resistance, and has a good performance in some scenes with high strength requirements such as work jigs and fixtures;

Features

High strength

Matte appearance

Carbon fiber frosted textureExcellent printability

High speed printingReview

- * Application

- * Print model

-

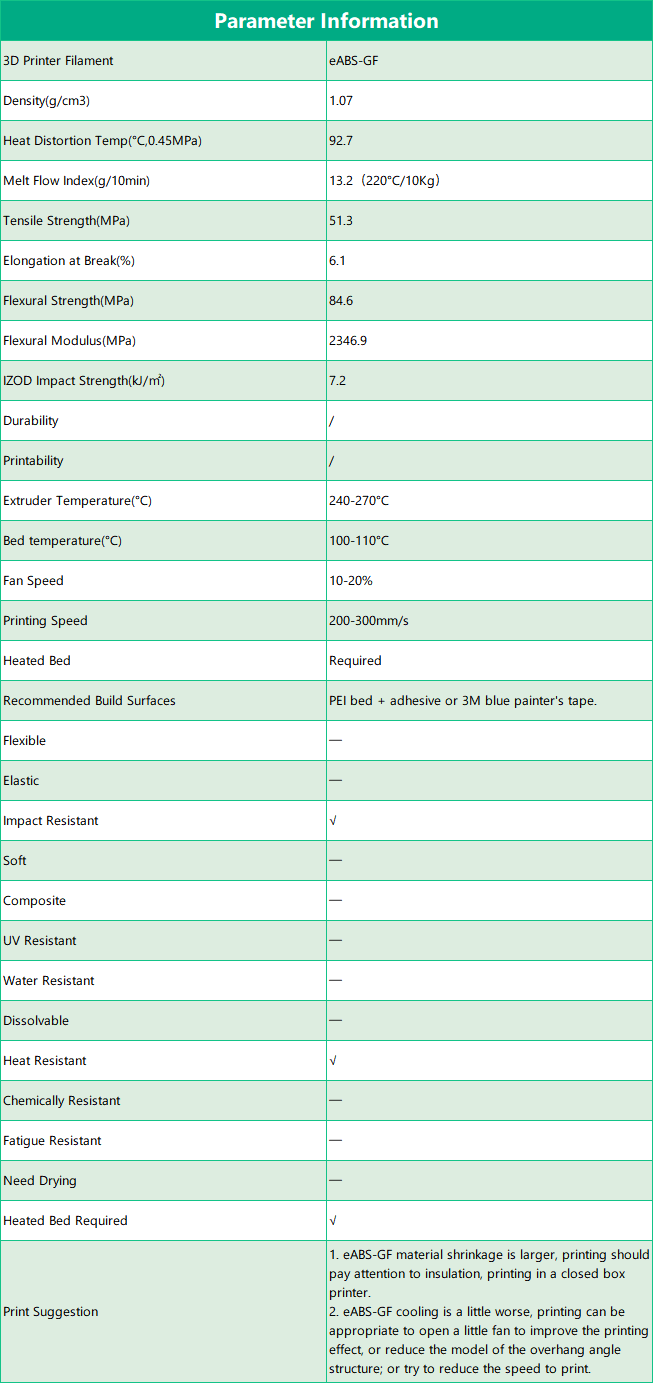

1. eABS-GF material shrinkage is large, printing should pay attention to heat preservation, printing in a closed box printer.

2. eABS-GF cooling is a little worse, printing can be appropriate to open a little fan to improve the printing effect, or reduce the model of the overhang angle structure; or try to reduce the speed to print.