Plugging

Plugging is usually caused by insufficient extrusion pressure inside the nozzle, resulting in insufficient fluidity of the material.

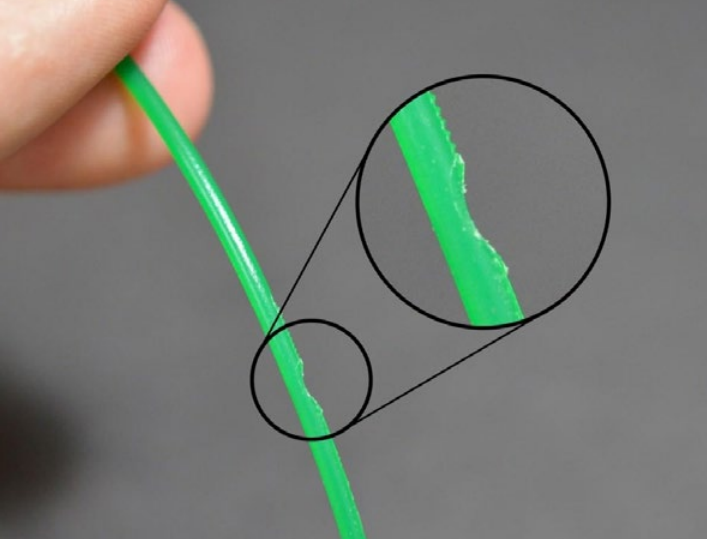

- Throat :The front end of the tube is obviously black after extraction, in addition, the Teflon tube exceeds 250 degrees for printing and the consumables (such as luminous) that wear nozzles will accelerate the aging plug and need to be replaced, it is recommended to use a metal hose or a special temperature-resistant print head for printing over 250 degrees .

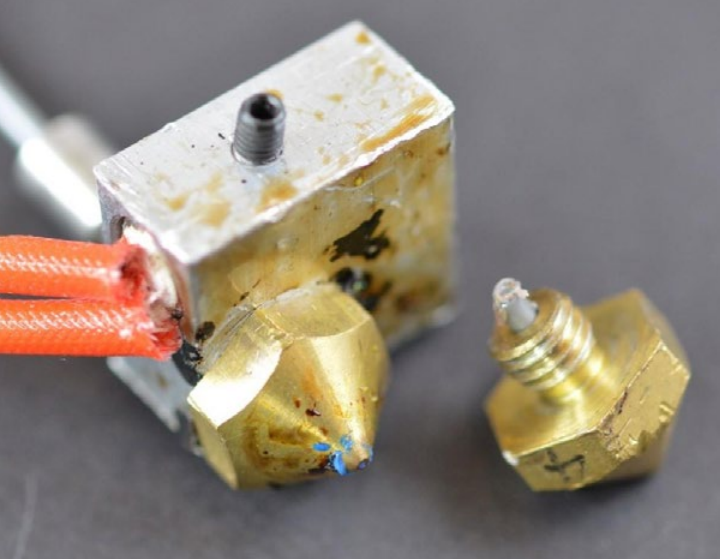

- Nozzle : Consumables are carbonized inside the nozzle for long-term printing, especially inferior nozzles. It is recommended to use sharp nozzles. You can try to clean or replace with clean filaments.

- In addition, for printing consumables with worn nozzles (such as luminous)), it is recommended to use ruby or hardened steel nozzles

- Temperature: The printing temperature is not enough, for example, ePA-CF is best to print at 280 degrees, if you use 240-250 degrees printing may block the head

- Speed: Some materials have poor fluidity and cannot be printed at too high speed, generally 40-60mm /s is a relatively appropriate speed

- Assembly:The nozzle is cold-tightened, causing the throat and the nozzle to not contact tightly, leaking material, and plugging. It should be heated to about 210℃ and tightened.

- Machinery: extruder adjustment is too loose, the material bite force is not enough, so it should be properly tightened

- Main board: The drive chip is overheated or the regulation current is too small, the extrusion motor is overheated or slips, and the current should be adjusted according to the requirements of the motor.

Post time: Sep-05-2021