ePEEK-Industrial

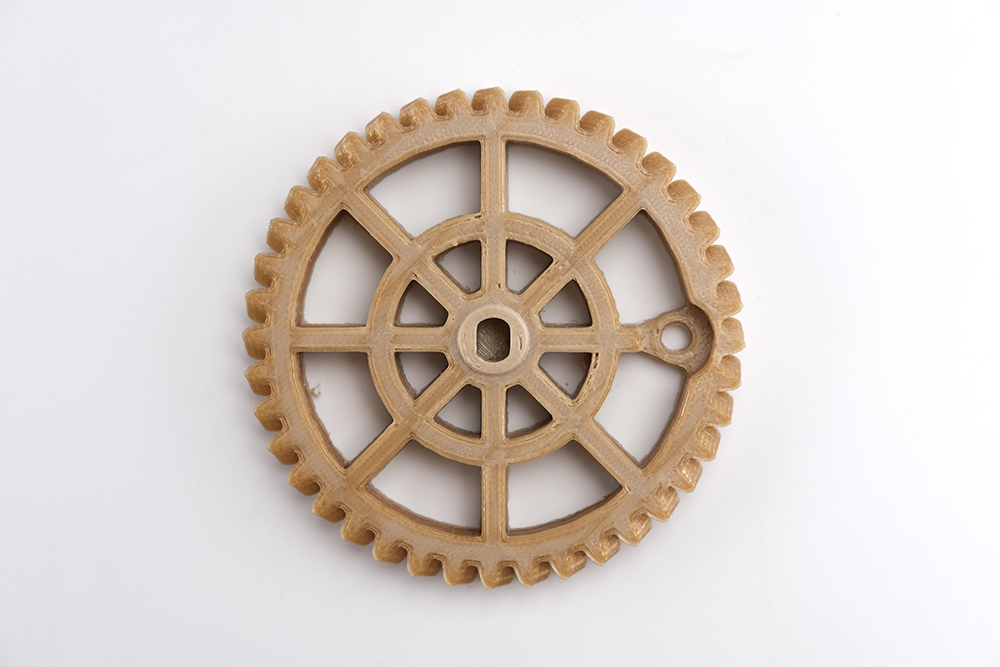

Special plastic materials with excellent mechanical and thermal properties; high strength, high toughness, impact resistance; self-lubricating and wear-resistant properties, printable mechanical gears; flame retardant; resistant to corrosion by most chemical reagents and solvents; high temperature resistance Performance, the heat distortion temperature is as high as 205℃, and it can be used for heat-resistant parts.

- * Description:

-

Description

Special plastic materials with excellent mechanical and thermal properties; high strength, high toughness, impact resistance; self-lubricating and wear-resistant properties, printable mechanical gears; flame retardant; resistant to corrosion by most chemical reagents and solvents; high temperature resistance Performance, the heat distortion temperature is as high as 205℃, and it can be used for heat-resistant parts.

Sellingpoint

Chemical resistance

Heat resistance

Flame retardantHigh toughness

High impact resistance

Abrasion resistance

- * Application

- * Print model

-

| Filament Properties Table | |

|---|---|

| 3D PRINTING FILAMENT | ePEEK-Industrial |

| Density(g/cm3) | 1.29 |

| Heat Distortion Temp(℃,0.45MPa) | / |

| Melt Flow Index(g/10min) | / |

| Tensile Strength(MPa) | 100 10/10 |

| Elongation at Break(%) | 40 4/10 |

| Flexural Strength(MPa) | 170 10/10 |

| Flexural Modulus(MPa) | 4200 7/10 |

| IZOD Impact Strength(kJ/㎡) | 6.5 1/10 |

| Durability | 10/10 |

| Printability | 6/10 |

| Recommended printing parameters | |

| Extruder Temperature(℃) | 380-440℃ Recommended temperature420℃ |

| Bed temperature(℃) | 130-150℃ |

| Fan Speed | 0-40% |

| Printing Speed | 20-40mm/s |

| Heated Bed | Required |

| Recommended Build Surfaces | PVP solid glue, high temperature glue |

| Feature | |

| Flexible | —— |

| Elastic | —— |

| Impact Resistant | √ |

| Soft | —— |

| Composite | —— |

| UV Resistant | √ |

| Water Resistant | √ |

| Dissolvable | —— |

| Heat Resistant | √ |

| Chemically Resistant | √ |

| Fatigue Resistant | √ |

| Need drying | √ |

| Heated Bed Required | √ |

| Print recommend | Drying at 80℃/>8h, try to increase the constant temperature chamber and the bottom plate temperature, and strictly adjust the level before printing |

1.It’s better to dry the ePC filament before printing(70℃/>6H).the eBOX is suggested to use when printing the ePC filament.

2.The shingkage of ePEEK-Industrial material is high.So pls use printer which has chamber to print the ePEEK-Industrial filament.

3.eePEEK-Industrial is prone to warping when printing. Pls increase thechamber temperature and plate temperature ; choose a bottom plate with high flatness and high temperature resistance; Leveling is required before printing.

4. Uneven crystallization of ePEEK-Industrial material may occur during the printing process. Try to increase the chamber temperature and reduce the cooling speed of the PEEK material; if necessary, an oven is required for post-annealing. Annealing after printing can improve mechanical performance. Put it in the oven 150 ℃/1h→200℃/1h→150℃/0.5h.

-

MSDS

MSDS -

TDS

TDS