See the development of Indian additive manufacturing through [Inside 3D Printing Mumbai]

2018/12/28

See the development of Indian additive manufacturing through [Inside 3D Printing Mumbai]

In 2018, under the high-quality development requirements of the technology industry, global additive manufacturing has entered a new round of industrial transformation and upgrading. The consumption patterns and demands of 3D printing have undergone new changes. The integration of culture, technology and education becomes to the important development momentum of 3D printing industry. However, for India, the development of 3D printing technology is slow, so India has been accelerating its catch-up, insisting on and vigorously promoting the “Made in India” campaign, aiming to transform India into a global design and manufacturing leader.

From December 19th to 20th, India’s largest 3D printing exhibition [Inside 3D Printing Mumbai] was successfully held at the Nehru Convention and Exhibition Center in Mumbai. This is a technology feast that combines 3D printing equipment, materials, technology and solutions. In addition to the participation of local Indian companies, it also includes 3D printing companies in other countries, covering 3D printing displays in aerospace, jewellery, hand-held models and other applications.

For example:

This 3D printing industrial manufacturing aircraft turbine is extremely refined. The human skull printed with photosensitive resin also confirmed the level of 3D printing in medical health applications.

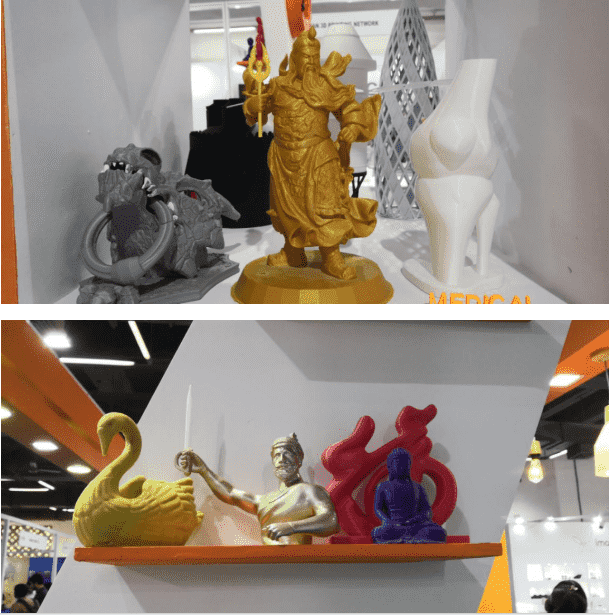

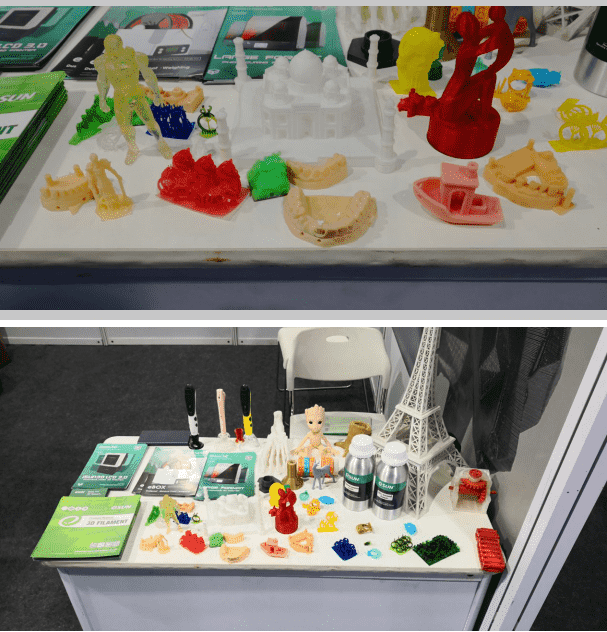

No matter for Guan Gong, or Indian saint or Chinese Buddhist, as long as you want to worship, you can print it out. The following models show the printing effect of our filaments. From the sample, you can see the gloss and hardness of the product at a glance, and whether the 3D printer prints smoothly.

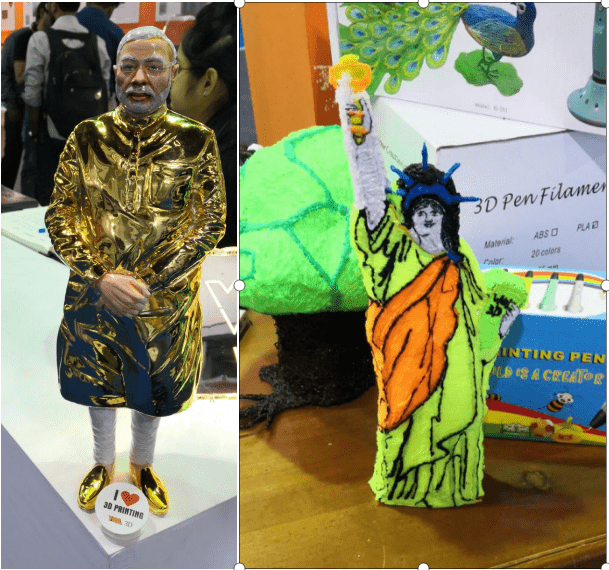

Of course, in addition to the original printing, the appropriate exquisite post-processing also makes the samples come alive. This skill has always been testing the creator’s polish ability; and the novel gameplay of 3D printing pens requires the endless renovation of makers.The following two represent the model.

The original printing effect of filaments is increasing. For example, eSUN, a world-renowned brand of 3D printing materials, its filaments of eCopper, Bronze, Wood, Color Change, etc. The effect is as its name, and this year, the silk smoothness and marble texture effect on the market is also popular. The following is a sample of such effects.

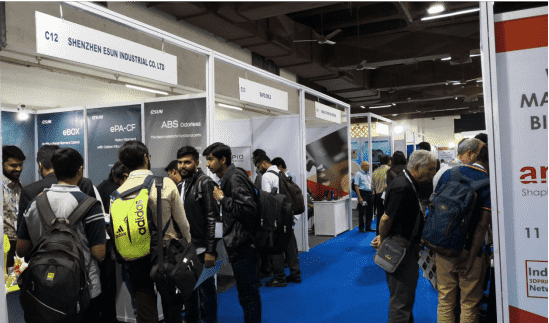

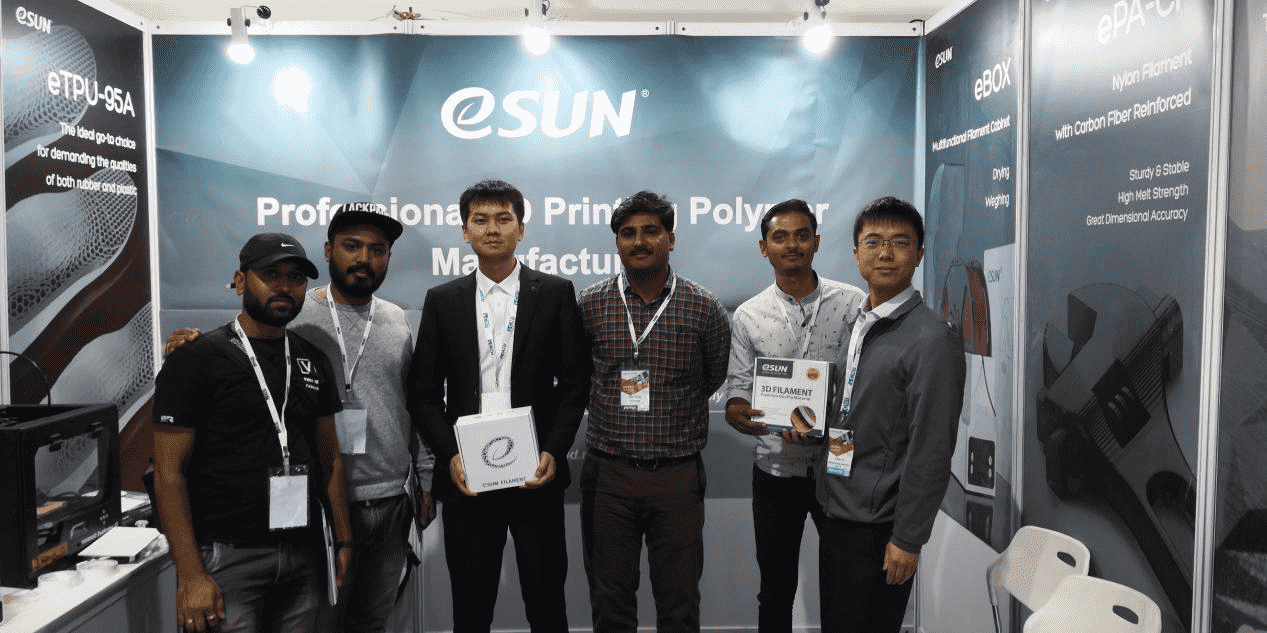

eSUN has been exhibiting in Mumbai, India for four consecutive years, and as the last stop of 3D Printing exhibition in 2018, eSUN must make it magnificent.

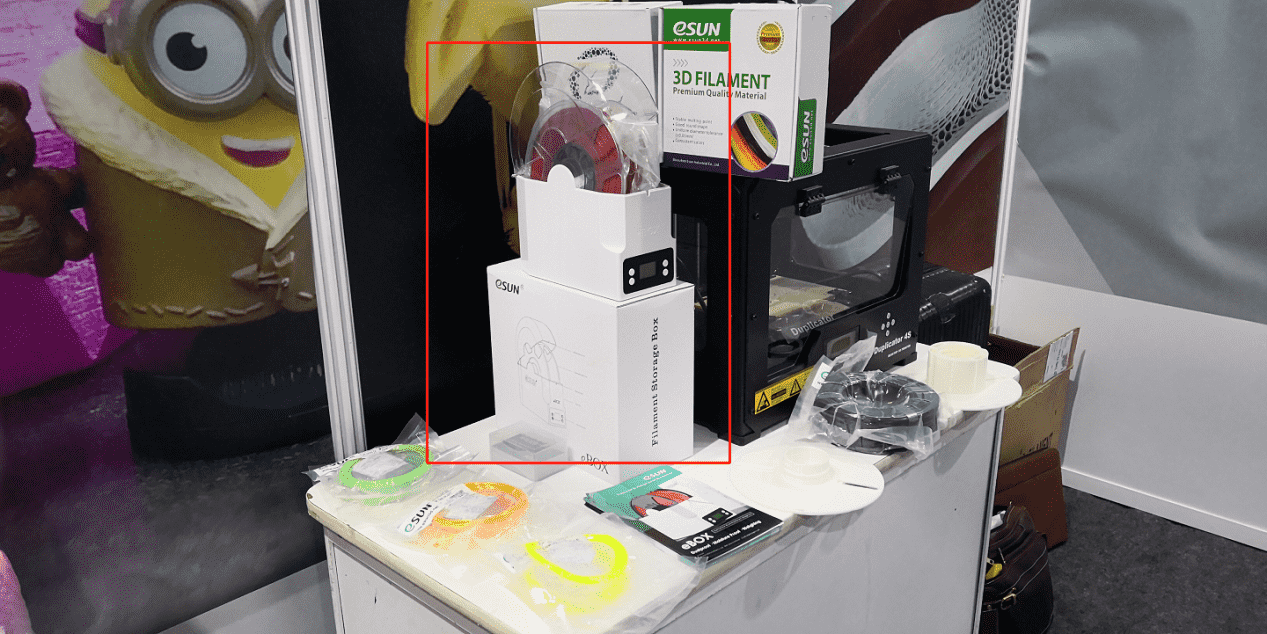

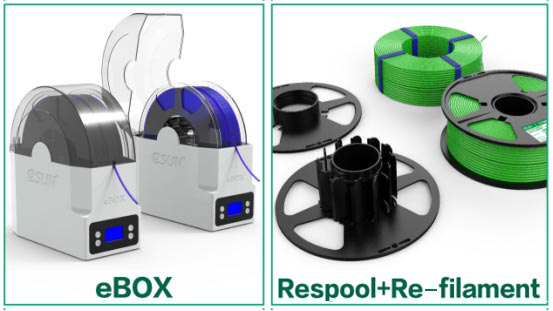

eSUN’s products at [Inside 3D Printing Mumbai] include: ultra-flexible and high-rebound eTPU-95A, nylon carbon fiber ePA-CF, four types of light-curing resin, PLA+ and [Refilament + eBOX + Respool ] and etc.

The most impressing thing is that many Indian jewelers came to the exhibition. eSUN’s DLP bio-based photosensitive resin eResin-PLA and DLP jewelry casting photosensitive resin were highly appreciated by these jewelers. The former is the world’s first bio-based, safe and environmentally friendly, with high printing precision, good hardness and scratch resistance. The latter has high definition and smooth surface. It is a very good choice for making jewelry models. eSUN’s DLP high-strength photosensitive resins and DLP dental casting photosensitive resin have also received much attention as light-curing technology materials. The four consumables are all environmentally friendly biomaterials.

Due to the climate impact in southern Asia, the water absorption and shrinkage of filaments in 3D printing products are also the key values for Indian visitors.

Some filaments are easy to absorb moisture in the air. When the water expands, it may cause rough surface and poor mechanical properties. For the consideration of Indian customers, eSUN introduced the new eBOX, which is used for heating and drying filaments anytime and anywhere. It also has functions of moisture-proof and dust-proof, and weighing and monitoring filaments’remaining condition.

Besides, eSUN also introduced Refilament and Respool. Refilament is neat and tidy,

reducing filament knotting; Respool can be reused, saving resources, perfectly solving the trouble of disposing of reel and saving transportation cost.

The interactive session is especially important. eSUN prepared small models printed by all kinds of filaments. Through friendly communication with customers and sending these small samples to partners who are interested in win-win, on the one hand, it fully demonstrates the diversity of filaments, on the other hand, it builds trust and interaction with partners . Many local people agree with eSUN’s popularity and appreciate eSUN as a representative brand of 3D printing filaments.

eSUN’s booth is full of visitors due to every popular product. And eSUN

carefully recording product’s suggestion also reflects eSUN’s determination and commitment to create quality products.

The above are all the highlights of this exhibition [Inside 3D Printing Mumbai].

World exhibition, we continue to move forward.

For more information about filaments and 3D printing equipment, please

scan QR code below to follow us!