eSUN 3D printing orthopedic insoles looking for agents and franchisees, undertake insole 3D printing service

2019/03/28

eSUN 3D printing orthopedic insoles looking for agents and franchisees, undertake insole 3D printing service

Orthopedicinsole manufacturing needs innovation, eSUN recommends3D printing

At present, most of the orthopedic insoles on the market adopt traditional manufacturing methods, and the process is cumbersome and expensive, mainly including manual manufacturing and CNC machining.

Among them, the manual manufacturing is hand-polished by the orthopedics, which is time-consuming and labor-intensive, and has a long manufacturing cycle and cannot be mass-production. CNC machining is subtractive material manufacturingwith large material waste, expensive equipment, largefloor space, complicatedoperation, and the processing process is noisy, dusty and extremely not environmentally friendly. These traditional manufacturing methods can not make the orthopedic insole popular and widely applied.

(traditional handmade insoles)

(CNC processing and manufacturing insoles)

eSUNaims at these features oforthopedic insole industryand appliesyears of experience in 3D printing materials and equipment, successfully developed 3D printing materials and 3D printers for orthopedic insole production, whichcreated the firstmedical insole 3D printing system in China.

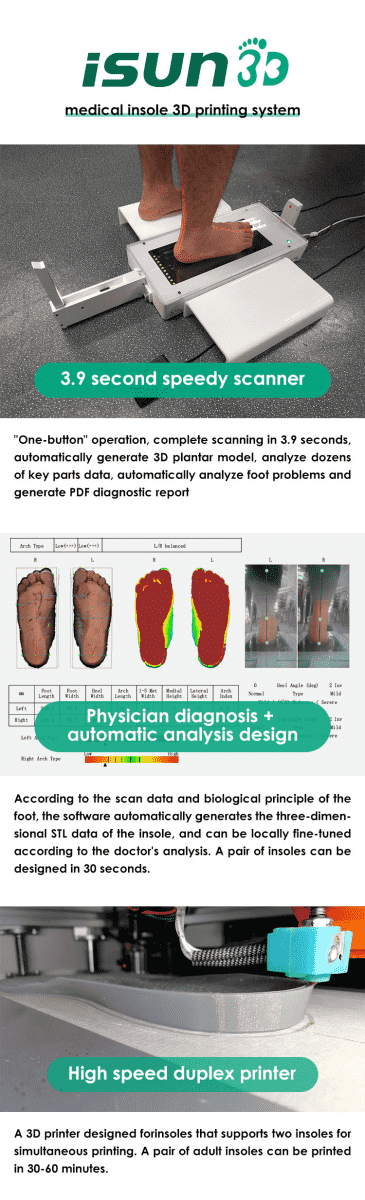

iSUN3D medical insole 3D printing system, The first in China

iSUN3D medical insole 3D printing system has greatly improved the efficiency, productivity, quality and cost of similar systems. eSUN also applied for patented technology, using 3D scanning to obtain user foot data, applying high soft TPU material and iSUN3D FLX printer to print a pair of insoles that are completely suitable for the user’s foot type to fix and maintain the foot health. Here are the details steps:

iSUN3D medical insole 3D printing system

Matched with eSUN eTPU-95Afilament

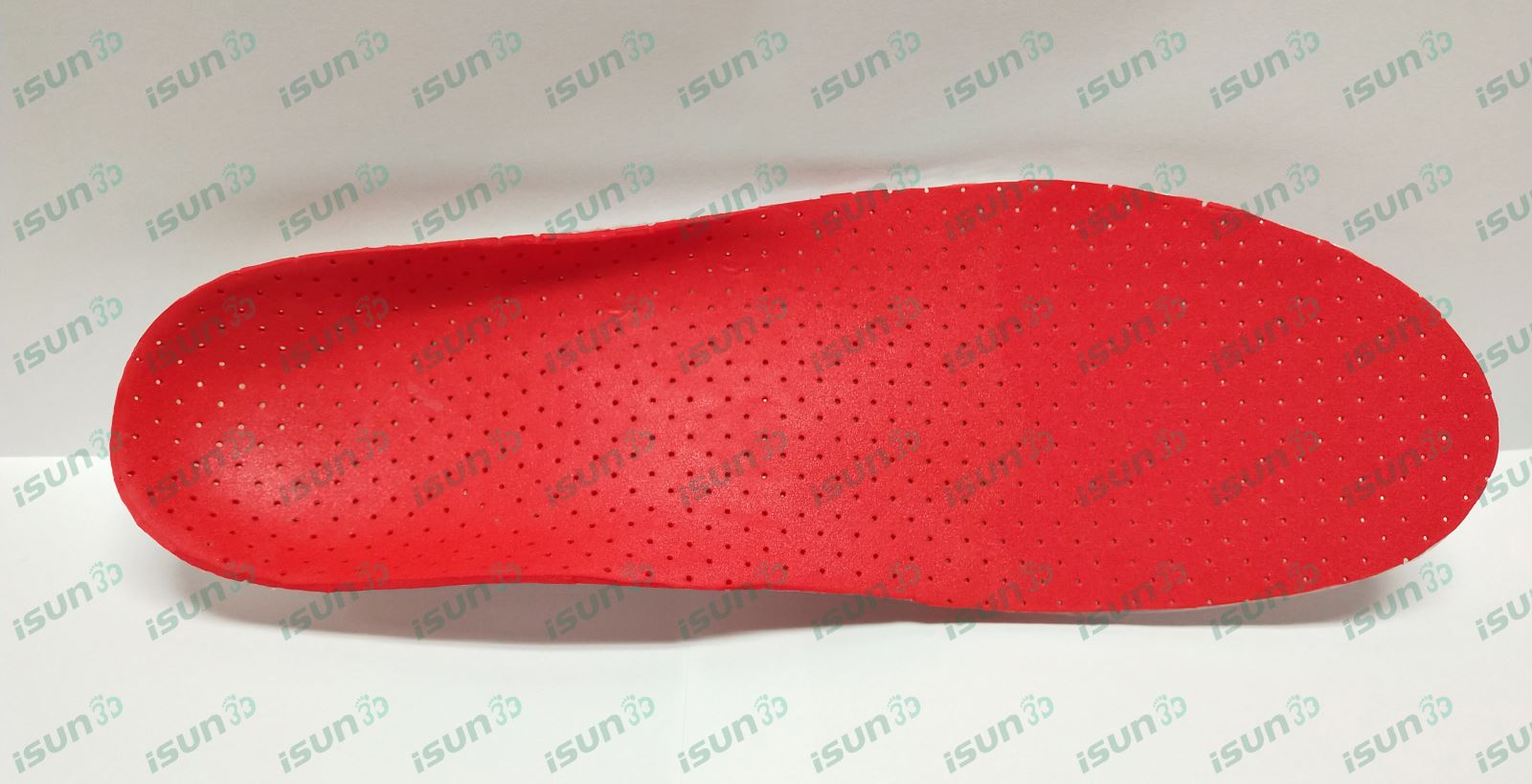

eTPU-95A has high flexibility and high resilience, which will greatly reduce the permanent deformation rate of the material. At the same time, it has moisture permeability and hydrolysis resistance, so that insolescan be washableand survive cold and warmconditions.It is highly transparentwith higher flexibility and hardness toensurestable print size and shape. As an environmentally friendly material,it prints smoothly with no odor and no need to heat the bottom plate when printing.The surface of the product is also easy to color.

Thematerialisbio compatible, safe and environmentally friendlyandiSUN3D FLX printercan printfast. Due to the breakthrough of 3D printing technology, the insole printingtimehas been shortened from 30 hours to 30-60 minutes, and the system is integrated and easy to operate. Undoubtedly, this technology will greatly improve the traditional manufacturing modes of hand-made and CAM.

(iSUN3D printedinsole)

Takingadvantage of 3D printing and sharingeSUN’s innovative resources

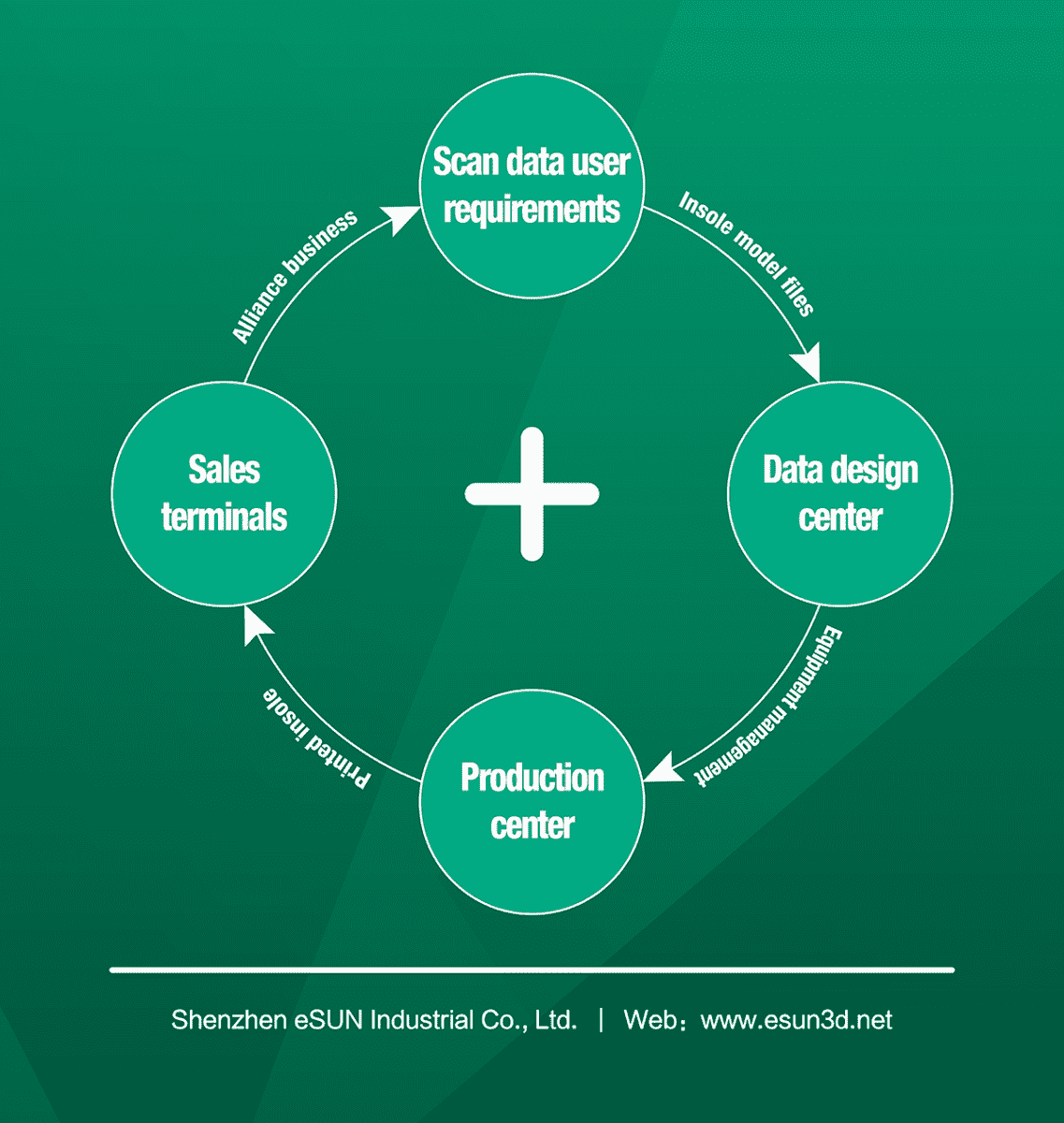

eSUNtakes advantage of its own materials, integrates global resourcestodevelopafoot scanning—design—3D printing—post-processing system and putit into practical use. It has established orthopedic insole design and 3D printingprocessing centerin Shenzhen and Hubei Xiaogan.eSUNhopes to build a scanning franchise network and a centralized design center by establishing a centralized print service center, thus forming a complete print service center—design center—distributed scanning network system. iSUN3D orthopedic insole 3D printing solution seamlessly interfaces with eSUN3D printing system, andshare eSUN design center and 3D printing processing center.

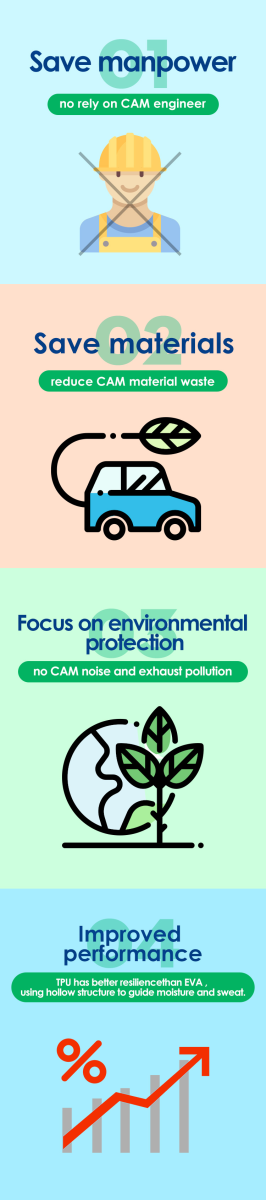

The scanning and design of current insoles arerelatively mature on the market, and orthopedic insoles are no longer only hand-made or CAM manufactured. The unique creation of eSUN3D printing insole system completely replaces the traditional orthopedic insole manufacturing process. Different from the production of CAM orthopedic insole, it has the following advantages:

(1) Save manpower,norely on CAM engineer;

(2) Save materials, reduce CAM material waste;

(3) Focus on environmental protection, no CAM noise and exhaust pollution;

(4) Improvedperformance,TPU hasbetter resiliencethan EVA , using hollowstructure to guide moisture and sweat.

In the future, breakthroughs in 3D printing technology will significantly improve the production of traditional orthopedic insoles.

(1) If you already have a foot scanner, eSUN will provide comprehensive design and printing services;

(2) If you have a foot scanner and the ability to design insoles, eSUN will provide print manufacturing services;

(3) If youhave non of the above but intendsto enter the insole medical field, eSUN will provide comprehensive training and a full affiliate program.

Open platform, shared business! iSUN3D orthopedic insole 3D printing solutionnow invitesagent franchiseeand also provides a large number of insole printing services.Please feel free to contact us!

Phone number: 0755-86581960

Email: bright@brightcn.net

QQ: 2304729480

WeChat: GWWYeSUN

Or you can leave a message below andwe will get in touch with you as soon as possible!