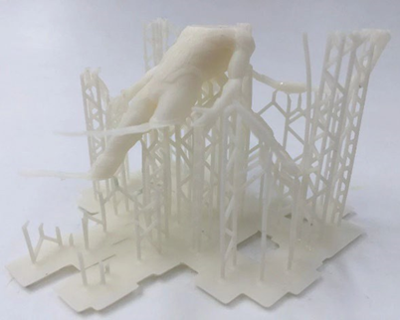

Support and model separation

|

|

| Support and model separation | Support missing or broken |

The printed model is separated from the support or part of the support structure is missing or broken

Screen: Cured dirty resin on the screen affects the release; or the screen leaks liquid causing the area to be unprintable or the degree of molding is reduced

Light source: Some light sources are not uniform, which may lead to inconsistent exposure in different areas

Resin: Resin viscosity is too high, it will lead to an increase in the release force, making the support and model separation, it is recommended to properly reduce the lifting speed and increase the lifting height

Model: sudden changes in the cross-sectional area of the model, such as a small area to a large area, increased release force, single-layer deformation, When placing it, try to avoid sudden changes in cross-sectional area and large areas directly supported

Slicing: insufficient exposure time, so that the model is not cured enough, resulting in support is too thin and too soft, During the stripping process, the support is separated from the model under a larger release force, it is recommended to test the exact exposure time before printing; support less thin, resulting in support can not pull the model, separation occurs, it is recommended to thicken encryption; lifting speed is too fast, there may be a larger release force, making support and model separation.

Separation: If the release film is worn out, the release force is not enough, resulting in the separation of the model paste bottom and support.

Temperature: the temperature is too low without insulation, and the resin activity is low, it is recommended to open air conditioning 25-35 ℃ for printing.

Post time: Dec-15-2021