Sticker Base&warp

|

|

| Sticker Base | warp |

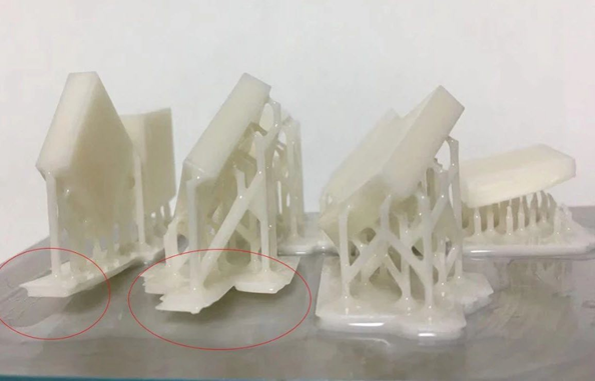

Printed models stick to the release film, or the corners buckle

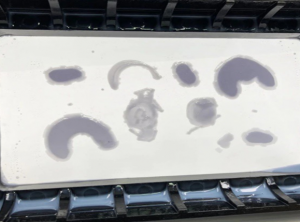

Screen: Cured dirty resin on the screen affects the release

Light source: Some light sources are not uniform light, which may lead to inconsistent exposure in different areas

Leveling: The platform and the screen leveling four corners are not level or too far away, should be re-leveled,The resistance of the A4 paper drawn from each corner is the same.

Platform: There are uncleaned impurities on the forming platform; the forming platform itself is not flat; the forming platform is worn.

Slicing: the bottom exposure time is not enough, increasing the bottom exposure time to improve the adhesion of the model and the bottom plate, the bottom exposure is 8-10 times the ordinary exposure time; lifting speed is too fast, the release force increases significantly

Release: If the release film wears out and ages, affecting the release force, resulting in a sticky bottom, you can try to replace the release film

Model: the model is placed, no drainage hole is added at the bottom, vacuum pulling is generated during the clamping process, clamping force plus vacuum pressure leads to detachment; sudden changes in the cross-sectional area of the model, such as small area to large area, clamping force increases, single-layer deformation, and vacuum pulling and sudden changes in cross-sectional area should be avoided as much as possible when placing

Post time: Dec-15-2021