Incorrect size

Size and design size have large deviation

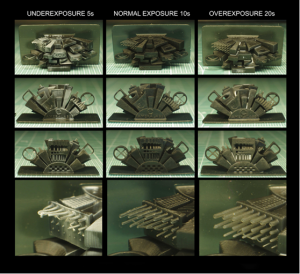

Slicing: Too short exposure time will cause the size to be too small and unable to form, too long exposure time will cause the size to be too large, and the details will be lost. It is recommended to test the exposure time before printing when using a new machine and resin; for inner hole parts, due to Resin shrinkage problem, you can adjust the tolerance compensation setting in the slice.

Light source: part of the light source is not uniform light, which may cause inconsistent exposure and size in different areas.

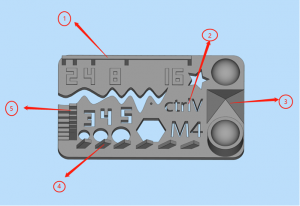

Exposure time calibration

Different resin and different printing have different exposure time, Generally, 5 thin columns are selected and measured with a vernier caliper. Use a vernier caliper to measure the 0.6mm elevation (size error within ±0.03mm) as the standard. If it is too small, the exposure will be increased. Larger reduces the exposure, generally the color screen adjusts the exposure range of 0.5-1.0s, the black and white screen adjusts the exposure range of 0.1-0.5s )

|

|

| Different exposure times | Exposure test model |

Post time: Dec-15-2021